czhongda@czhongda.com.cn

czhongda@czhongda.com.cn

SEARCH...

SEARCH...

czhongda@czhongda.com.cn

czhongda@czhongda.com.cn

SEARCH...

SEARCH...

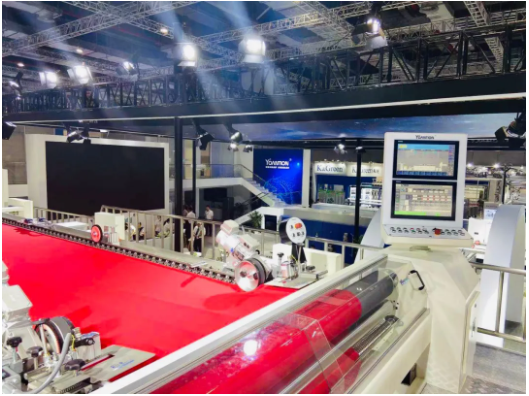

During the 2020 textile machinery joint exhibition, the inshk shaping intelligent system launched by Changzhou Hongda Technology (Group) attracted the attention of many viewers.

Inshk intelligent setting system is a comprehensive improvement of the existing setting machine. It is a complete process execution system of the setting machine, which is built by means of big data, process Internet and artificial intelligence technology. It ensures the setting quality of textiles and constructs the control mode of a new generation of setting machine, It will greatly improve the existing intelligent degree of setting processing.

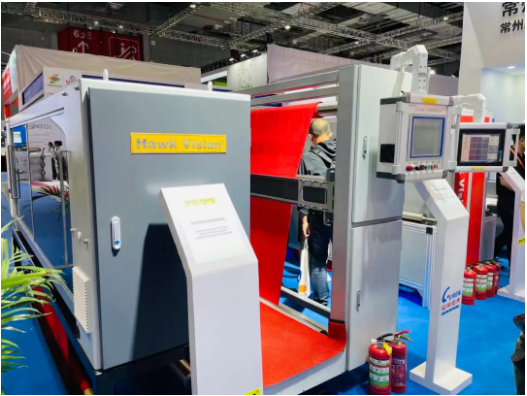

Among them, hawk vision density detection overfeeding automatic control system can realize high-speed image measurement, has the patent technology of jitter compensation, high measurement and control accuracy, strong adaptability of fabric varieties, good operability, and has the price advantage. Hv-gm200 intelligent online weighing instrument can realize real-time online accurate automatic measurement of weight; Solve the problem of manual weighing; Ensure the high quality of products in the whole process; Greatly reduce the loss in the production process; With hawk vision densitometer; The closed-loop target weight control is constructed; It can realize the on-line detection, gram weight and door width real-time on-line record storage and data query; Support enterprises to realize intelligent manufacturing.

Gu Ren, chairman and general manager of Changzhou Hongda Group, told China Textile News that inshk setting intelligent system has realized the accurate measurement and control of temperature and setting time in the setting process, realized digital and accurate setting, and ensured the high-quality setting effect of fabrics. The system is convenient for staff to know the real-time status of key process parameters in time, greatly improve the overall quality control ability of users, and ensure the quality control of production process. Through deep learning of big data and artificial intelligence, online detection of various process parameters, the intelligent system of setting machine independently optimizes and generates the setting process to ensure the reproducibility of the process and the one-time success rate of new product setting. At the same time, the complete shaping process execution system constructed by using big data, industrial Internet and artificial intelligence technology can also dock with the enterprise cloud.

During the exhibition, Yuanxin Industry Co., Ltd. focused on y9000 series double-layer hot-air stenting and setting machine, which deeply integrated inshk setting intelligent system, realized the comprehensive collection of data on the types and target quality of textiles, processing technology and operation status of setting machine, and established a perfect setting process database, Complete the setting process for Intelligent Implementation and comprehensive monitoring, well received by users.

Gu Ren said that inshk shape setting intelligent system has opened a new era of accurate weight control without engraving, led the shape setting process control into the era of artificial intelligence and become the "standard" of high-end shape setting machine.