czhongda@czhongda.com.cn

czhongda@czhongda.com.cn

SEARCH...

SEARCH...

czhongda@czhongda.com.cn

czhongda@czhongda.com.cn

SEARCH...

SEARCH...

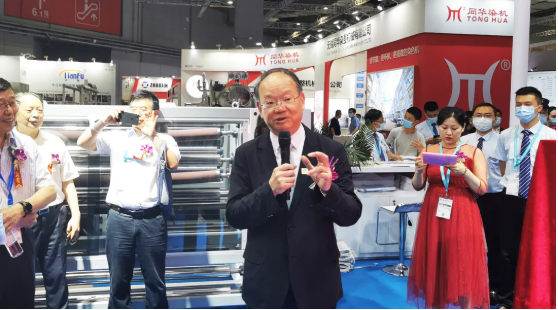

[printing and dyeing learning and exchange] Caiye's on-site report: at this ITMA Asia + CITME 2020 exhibition in Shanghai, general manager Gu of Changzhou Hongda Group officially released the latest "Hawk vision" to the world ® Flexible intelligent weft trimmer "makes weft trimmer enter a new era of intelligence! Here's the story

Gao Yong, Secretary of the Party committee of China Textile Industry Federation

At the launching ceremony, Gao Yong, Secretary of the Party committee of China Textile Industry Federation, affirmed the grand development of Changzhou. He said that Changzhou Hongda has been specialized in the research and development of digital online measurement and control products for textile printing and dyeing for many years, and is known as "intelligent expert of printing and dyeing" in the industry. Its online detection products for printing and dyeing process parameters account for more than 90% of the domestic market. In 2020, Changzhou Hongda was awarded by China Textile Machinery Association to establish the product R & D center of image weft trimmer. Now the weft trimmer has made new breakthroughs and innovations. Changzhou Hongda's scientific research achievements have played a very good leading role in the high-quality development of the textile industry.

Gu Ren, chairman and general manager of Changzhou Hongda Technology (Group), told China Textile News that hawk vision ® At present, the flexible intelligent weft trimmer has been tested and run in many user enterprises, and has achieved very good results, which is highly praised by users. More than 30 patents make the device more competitive in the market. After today's press conference, many directional inquiries were received, and many users and enterprises expressed their intention to order. Gu Ren said that although the market is still affected by the epidemic, the company's sales performance has improved steadily. In the first half of this year, the company's product sales have increased significantly compared with last year, and it is expected to maintain a good state throughout the year.

Group photo with Gu Ren, chairman and general manager of Changzhou Hongda Technology (Group)

In Gu Ren's view, equipment manufacturers pay more attention to the machinery manufacturing itself to meet the basic needs of users, while Changzhou Hongda is an intelligent way to meet the core needs of users in terms of technology. In order to realize the intellectualization of printing and dyeing, we must first digitize the printing and dyeing process, and avoid conceptualization, fuzziness and experience. As we all know, in the era of intelligence, all walks of life are praising digitalization as "digital oil", but first of all, "where does data come from"? You can't fill in the form manually; Second, "how to use data"? These are the problems that need to be solved in the printing and dyeing industry, and also the place where Changzhou Hongda is making efforts“ The setting machine and dyeing machine are the main equipment in a printing and dyeing factory. The intellectualization of these two machines is an important foundation for the intellectualization of printing and dyeing as a whole. " Gu Ren said.

Taking the setting machine as an example, during the exhibition, Yuanxin industry focused on displaying y9000 series double-layer hot air stenting setting machine, which deeply integrated Changzhou grand hawk vision ® The new generation of process execution system of setting machine based on artificial intelligence technology is introduced, which realizes the comprehensive collection of data of textile types and target quality, processing technology, and running state of setting machine, and develops and designs a perfect setting process database to carry out intelligent implementation and comprehensive monitoring of the setting process. In addition, the setting machine is also equipped with hv-pc high-precision density on-line measurement and control system, hv-gm200 intelligent fabric weight on-line detector and fabric drop width on-line measurement and control system.

During the exhibition, Changzhou Hongda also showed inshk intelligent setting system, intelligent image finishing machine, knitting setting automatic weight on-line measurement and control system, round net defect detection and automatic pattern matching system, hydrogen peroxide on-line detection system, intelligent fabric inspection machine and other products. Among them, hawk vision ® Based on its strong European technical background and Changzhou's profound technical R & D strength, the intelligent image finishing machine is the first international leading "full scan finishing technology".