czhongda@czhongda.com.cn

czhongda@czhongda.com.cn

SEARCH...

SEARCH...

czhongda@czhongda.com.cn

czhongda@czhongda.com.cn

SEARCH...

SEARCH...

Editor's note:

Recently, a number of central media reported on the new look and development of China's textile industry, making more people understand that China's textile industry is no longer the traditional labor-intensive industry in people's minds. Taking advantage of the "east wind", China Textile Magazine opened up a column "this is China's textile". One is to transmit the central media's report on China's textile industry, The second is to show the leading enterprises that have made samples for the intelligent development of the industry in the aspect of high and new technology in the industry, publicize their way of success, and help the high-quality development of China's textile industry.

Different from the past, technological innovation has become the driving force to boost the development of the textile industry.

After the "13th five year plan" honed growth, "textile power" goal has been initially achieved, China's textile industry has become one of the world's five advanced manufacturing industries. At the enlarged meeting of the executive director of China Textile Federation recently, the development outline of the textile industry in the 14th five year plan was officially released. The outline clearly listed "strengthening the strategic support capacity of scientific and technological innovation" as the key task of the 14th five year plan, among which "intelligent manufacturing of printing and dyeing industry" was the key technology to be urgently broken through.

Printing and dyeing is a very special and highly concerned link in the textile industry chain. The development of "green" and "intelligent" dimensions has always been a hot topic. In the recent closing ITMA Asia + citme2020, a number of new products in the printing and dyeing industry were released, attracting extensive attention from both inside and outside the industry. Among them, Changzhou Hongda Technology (Group), known as the "intelligent expert of printing and dyeing", released a number of the latest intelligent products, which were affirmed by Gao Yong, Secretary of China Textile Industry Federation and his party, and became the most popular "star enterprise" in this textile machinery exhibition.

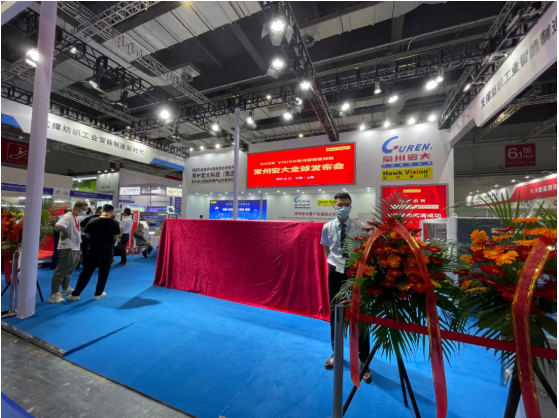

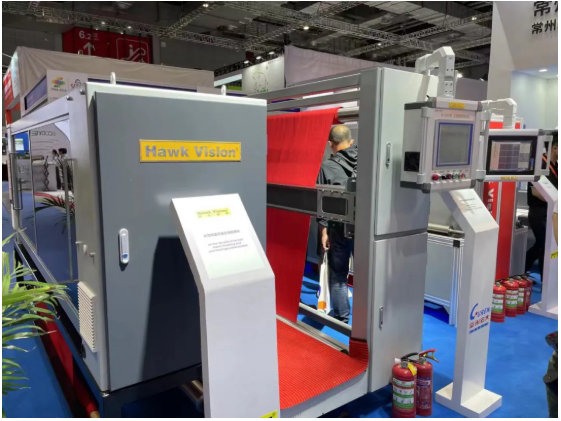

Hawk Vision ® Flexible intelligent weft trimmer launched in the world

Industry leaders and experts praised it one after another

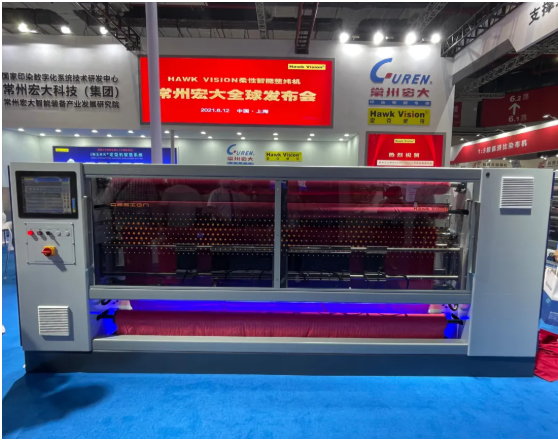

Recalling the first day of the textile machinery exhibition, in the dazzling exhibits and overwhelming topics, our new media editing reporter team stepped on the "battle" of the first line interview. When you come to Changzhou grand booth, the first thing you see is a "big" machine with a "red cap". This machine is hawk vision, the world's first launch of Changzhou grand in this textile machinery exhibition ® Flexible intelligent weft trimmer.

Changzhou Hongda is specialized in the research and development of digital online measurement and control products for textile printing and dyeing. The online detection products of printing and dyeing process parameters developed by Changzhou Hongda occupy more than 90% of the domestic market. For 30 years, Changzhou Hongda has been committed to innovation. In 2020, Changzhou Hongda was awarded by China Textile Machinery Association to establish the "R & D center of image flower weft finishing machine products" in China's textile industry, Today, the weft knitting machine has made a major breakthrough and innovation, which is undoubtedly attracting much attention.

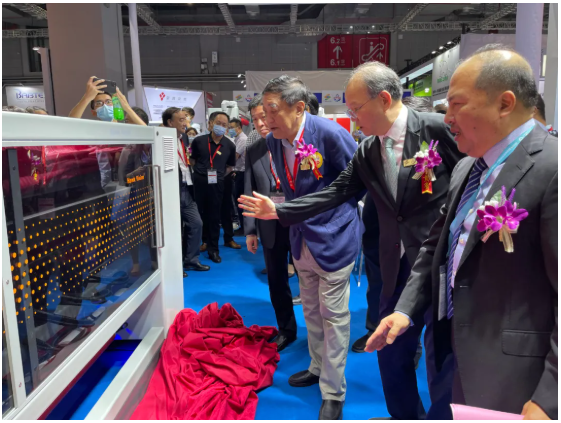

Before the global launch, this mysterious new product attracted a large number of audiences, and all of them paid close attention to Changzhou grand people inside and outside the industry. With the arrival of leaders from China Textile Industry Federation, this mysterious new product has finally revealed its true appearance.

Hawk vision released by Changzhou Hongda Technology ® Relying on its strong European technical background and Changzhou's great and profound technical R & D strength, the flexible intelligent weft trimmer is the first international leading "full scan weft trimmer technology". It has made original innovation from the weft trimmer mechanism, fundamentally changed the existing weft trimmer's weft trimmer method, and solved the problems of S-bend, w-bend, w-bend, S-bend, w-bend, and so on It is especially suitable for the correction of weft bending arc of knitted and woven fabrics, such as low tension, large skew and irregular weft. It ushers in a new chapter in the development history of weft trimmer.

Gao Yong, secretary general and former president of China Textile Industry Federation; Chen Weikang, deputy secretary of the Party committee; Yu Jianyong, academician of Chinese Academy of engineering; Li Lingshen and sun Huaibin, vice presidents of China Textile Industry Federation; Gu Ping, President of China Textile Machinery Association; Chen Zhihua, President of China printing and Dyeing Industry Association; and China Industrial Textile Industry Association, China Textile Engineering Society, School of mechanical engineering, Donghua University, Jiangsu textile engineering society, Wuxi Textile Machinery Quality Supervision and inspection center, Hengtian Lixin group, Zhejiang Yuanxin Industry Co., Ltd., Shaoyang Textile Machinery Co., Ltd., Sanderson (Shanghai) Textile Machinery Co., Ltd Relevant responsible persons of Jiangsu Hengjin printing and Dyeing Machinery Co., Ltd., Shandong Yueyue home textile, Zhejiang Zhuoda printing and dyeing, Ningbo Shengtai textile and other units attended the press conference. It can be said that the stars are shining. Each leader represents the authority in his field and gathers many industry leaders. We can see the Hawk vision of Changzhou grand technology ® The technical content of flexible intelligent weft trimmer is a milestone for the intellectualization of printing and dyeing industry.

Gu Ren, chairman of Changzhou Hongda, said in an exclusive interview with our reporter: "at present, only China can do this technology, while only Changzhou Hongda can do it in China." Gu Ren said: "at the beginning of our business 30 years ago, we made clear our development goals. For more than 30 years, Changzhou Hongda has been keeping pace with advanced control technology, insisting on innovation and sticking to our own way. Today, our flower and weft knitting machine has reached the world's leading level and won the first prize of science and technology progress of China Textile Industry Federation, This original technology has ended the era of printing and dyeing industry with only weft and no flower. The latest hawk vision ® Flexible intelligent weft trimmer will become the technical benchmark in this field again. "

Gao Yong, Wang Tiankai and other leaders were interested in the new machine after the red cloth was opened. They stopped in detail and asked for a long time before they explained the problem. Gao Yong said: "Changzhou Hongda has been focusing on the innovation and upgrading of image technology in the field of weft weaving. The new product has the leading role in the advanced technology. I hope Changzhou Hongda can strengthen its promotion and make more contributions to the high-quality development of China's textile industry. "

It is reported that hawk vision ® At present, the flexible intelligent weft trimmer has been tested and run in many user enterprises, and has achieved very good results, which is highly praised by users. After the press conference on the same day of the textile machinery exhibition, we received a lot of directional consultation, and many user enterprises expressed their intention to order.

Inshk finalized intelligent system

"Standard configuration" system of "deep intelligence" in dyeing factory

As a "printing and dyeing intelligent expert", Changzhou has made great achievements in the field of textile printing and dyeing intelligent with decades of technology accumulation. Changzhou grand hawk vision ® The new generation of process execution system (inshk) based on artificial intelligence technology has also become the focus.

Gu Ren told the reporter: "now most of the setting machines in dyeing factories only play the function of creating the environment, but the state of the fabric in the setting process and the setting effect are not monitored, which makes the setting of some special fibers and functional finishing, or fabrics with relatively high requirements can only be judged by the experience of the operators, It is subjective; Because it is impossible to realize the quantitative evaluation of the standard, which leads to the uncertainty of the final effect, some enterprises can't make a decision once or twice, which lowers the production efficiency. " Changzhou Hongda's "inshk finalization intelligent system" fundamentally solves this problem. Based on the industrial Internet, big data and the blessing of artificial intelligence technology, it can make independent decisions on the finalization process and form the process formula, so as to improve the efficiency of the dyeing factory.

As we all know, the setting machine and dyeing machine are the main equipment of the printing and dyeing plant, and to achieve the intelligent printing and dyeing process, we must first realize the "process digitization". The setting machine equipped with Changzhou Hongda inshk setting intelligent system can not only intelligently implement and comprehensively monitor the setting process, but also establish the setting process database for the enterprise.

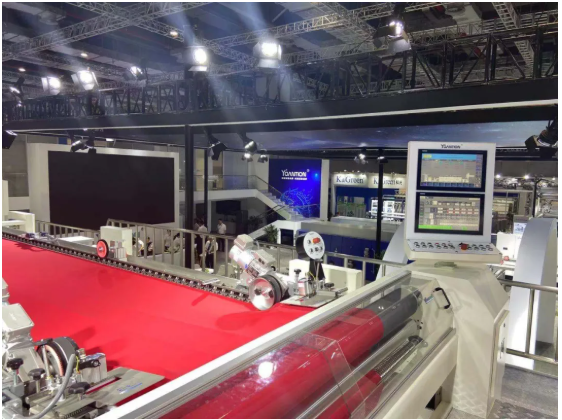

It is reported that the y9000 series double-layer hot air stenting and setting machine, which is the key display of the textile machinery exhibition Yuanxin industry, is deeply integrated with Changzhou Hongda system.

"Hawkvision has launched a new generation of process execution system of setting machine based on artificial intelligence technology, and has achieved deep intelligent integration with Yuanxin y9000 series double layer hot air stenting and setting machine. It has realized comprehensive collection of data of textile types and target quality, processing technology and running state of setting machine, and developed and designed a perfect setting process database, Intelligent implementation and comprehensive monitoring of the finalization process. " Gu Ren, chairman of Changzhou Hongda Technology Group, said that his years of cooperation with Yuanxin industry made him feel the resonance between the two companies in product innovation ideas and practices.

It is reported that the setting machine is also equipped with hv-pc high-precision density on-line measurement and control system, hv-gm200 intelligent fabric weight on-line detector and fabric drop width on-line measurement and control system, all from Changzhou Hongda.

Hv-pc high-precision density on-line measurement and control system adopts international leading digital image processing, pattern recognition, information fusion and other technologies, uses industrial cameras as detection elements, comprehensively uses them to detect the weft density of cloth in motion in real time, and adjusts the weft density of fabric in real time according to the weft density detection results, so as to make the weft density reach the ideal state, To ensure the realization of high quality textiles. The system overcomes the shortcomings of photoelectric detection and ordinary image detection, greatly improves the product quality and reduces quality complaints; Reduce the labor intensity of workers, reduce the requirements for operators' skills and experience, and avoid mistakes; Strictly detect and control the vehicle speed to reduce energy consumption and production cost; Greatly enhance the competitiveness of products and brand image of enterprises. The technology of this product has the national invention patent right.

Hv-gm200 intelligent fabric gram weight online detector realizes direct online weight detection, real-time continuous online recording and storage of fabric gram weight, real-time detection of cloth falling door width, networking with density detection overfeed system, and directly constructs closed-loop target gram weight control. The system greatly improves the consistency of fabric gram weight, greatly reduces the times of manual sampling and weighing, reduces the waste of fabric caused by sampling, and reduces the labor intensity of workers; It can reduce the large area of color difference caused by the holes in the engraving plate when printing. At the same time, it helps the dyeing factory to solve the weft arc problem caused by too much blanking tension, and ensures the product quality during setting. The product is used for the first time, which solves the online detection of key quality indicators that the industry needs to solve for a long time.

Inshk shaping intelligent system, intelligent image finishing machine, knitting shaping automatic weight on-line measurement and control system, circular mesh defect detection and automatic pattern matching system, hydrogen peroxide on-line detection system, intelligent fabric inspection machine... Changzhou Hongda has been deeply engaged in the printing and dyeing industry, focusing on intelligent development, and has become an important participant and leader in the high-quality development of the textile printing and dyeing industry.