czhongda@czhongda.com.cn

czhongda@czhongda.com.cn

SEARCH...

SEARCH...

czhongda@czhongda.com.cn

czhongda@czhongda.com.cn

SEARCH...

SEARCH...

ITMA is a trend-setting textile and apparel technology platform that meets every four years to explore new ideas, seek solutions to new solutions, and create opportunities for win-win cooperation. At the exhibition, the number of Chinese exhibitors ranked second (276), surpassing Germany (222), India (169) and Turkey (164). It shows that Chinese companies are more confident in the international arena and showcase Chinese manufacturing and Chinese creation on the same stage.

Which Chinese manufacturing is changing the traditional view of users around the world? Which companies have introduced new product technologies that are eye-catching? During this exhibition, we will continue to launch a series of reports [Directly hitting ITMA · They are changing the world] and take you to the scene to see the new changes in this exhibition.

China Textile Machinery's entire industrial chain intelligent advantage leads the world

Jingwei intelligence

JWF1589 new high-speed intelligent series ring spinning machine Jingwei intelligent textile machinery. According to the development trend of the current ring spinning machine, a new high-speed intelligent series ring spinning machine developed according to the existing mature technology and international advanced structure. The machine adopts modular design and industrial integration design. The steel collar plate and the guide plate adopt the active and stable active lifting system, with electronic twisting, electronic drafting or mechanical drafting technology, and the quick installation of the whole box. Slub yarn system, compact spinning device, single spindle inspection system, roving stop feeding device and spandex core yarn device are available for users to choose. The machine has higher stability and reliability at 22000~25000 rpm. Sex.

Beijing Jingwei New Technology

Jingwei e system has been committed to comprehensively solve the problems of factory information islands, management efficiency and production efficiency in the textile industry. Through the data collection of cotton spinning equipment as the center, a complete intelligent information acquisition system for the Internet of Things will be built, using intelligent gateway design, protocol converter, digital filtering technology, bus technology, RFID (radio frequency identification) technology, laser radar navigation technology, etc. . The machine operation data, product quality data, environmental data, energy consumption data, personnel data, etc. of the textile workshop will be built for the enterprise to build a big data platform, carry out in-depth analysis, and reverse the production management with data analysis.

Realize the "smart scheduling" with the order process as the core, optimize the scheduling, and tap the equipment production capacity; realize the order progress warning, the equipment status warning, the quality exceeding the standard warning, the environmental over-standard warning, and the energy consumption exceeding the standard warning. To build a “integration and control integration” platform for textile enterprises, and to achieve a double improvement in the management efficiency and economic benefits of textile enterprises.

Yichang Textile Machinery

K3501 straight twisting machine is suitable for the processing of nylon, polyester, aramid yarn, rayon, etc. It is used to produce double-strand cord and industrial thread with symmetrical structure. The machine has large package, low energy consumption, less labor, and finished product. The quality of the cord is high.

The cord has a wide range of applications and can be applied to tire cord fabrics, conveyor belts, transmission belts, cables, geotextiles, and the like. The machine can also be used to twist various BCF filaments (polyester, nylon, polypropylene, etc.), synthetic fiber filaments and spun yarns. Main features: High efficiency: electric spindle drive, the highest mechanical spindle speed of 11000RPM.

Qingdao Hongda

ROSS remote operation and maintenance system is a new generation of intelligent platform built by Qingdao Hongda for three years. It uses information technology, intelligence, big data and other technical means to transform the current manufacturing and service model and build a bridge with customers. Help customers quickly solve equipment failures, improve production efficiency, strengthen equipment management, and improve economic efficiency.

Warp and weft components

Based on the arrival of the intelligent era of textile machinery industry, Jingwei special parts in the positioning and development of textile machinery components, deep integration of new Internet technologies in product manufacturing, optimization of production methods, investment methods, management methods and business models , transformation and improvement of product manufacturing level.

Zheng Textile Machinery

ZKB412-180 automatic winding head spindle length is 1800mm, which is the widest winding head. The requirements for structural design, part processing and assembly quality are higher. Based on the original mature ZWB series winder, the digital continuous contact pressure control, the bottom small coil quality improvement mechanism, and the optimization of the upper push mechanism are optimized. The introduction of the ZKB series winder can better meet the special varieties. The production process requirements, and improve the finished product quality of polyester filament POY raw silk, at the same time adapt to the scale and intelligent development needs of the winding equipment, using a very intelligent control box, after the equipment is delivered to the user, just plug in the power supply It can be fully automatic, very easy to debug, and closer to the market and customer needs.

China Textile Technology

China Textile Technology continues to research and develop the spinning and fusion composite nonwovens production line, and has the ability to design and develop various new industrial textile complete sets of equipment and new composite fiber materials. The products have achieved in many varieties, high speed and high stability. Significant results are high-end suppliers of spun-melt nonwoven production lines. This exhibition will show the technical level of the company's spun-melt nonwoven production line to international customers.

Otfa

As nonwovens manufacturers face increasing competition, customers need to find reliable and economical machines that require not only high product quality but also the best total cost of ownership (TCO). Aotefa's nonwovens line meets customers' requirements for high quality web formation, web reinforcement, aggressive weight adjustment and reduced maintenance.

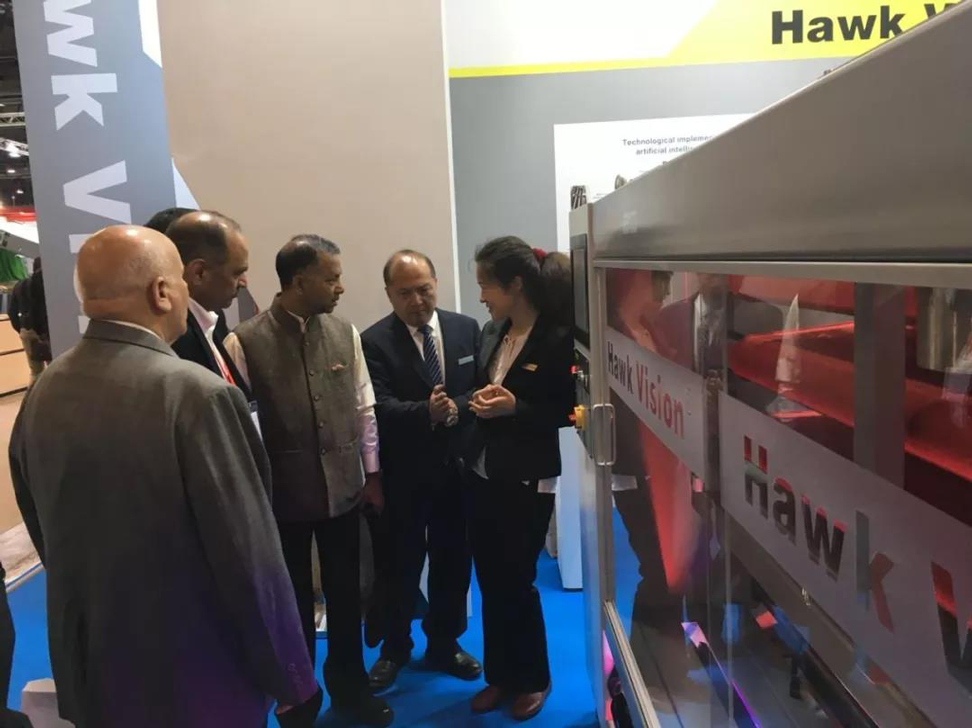

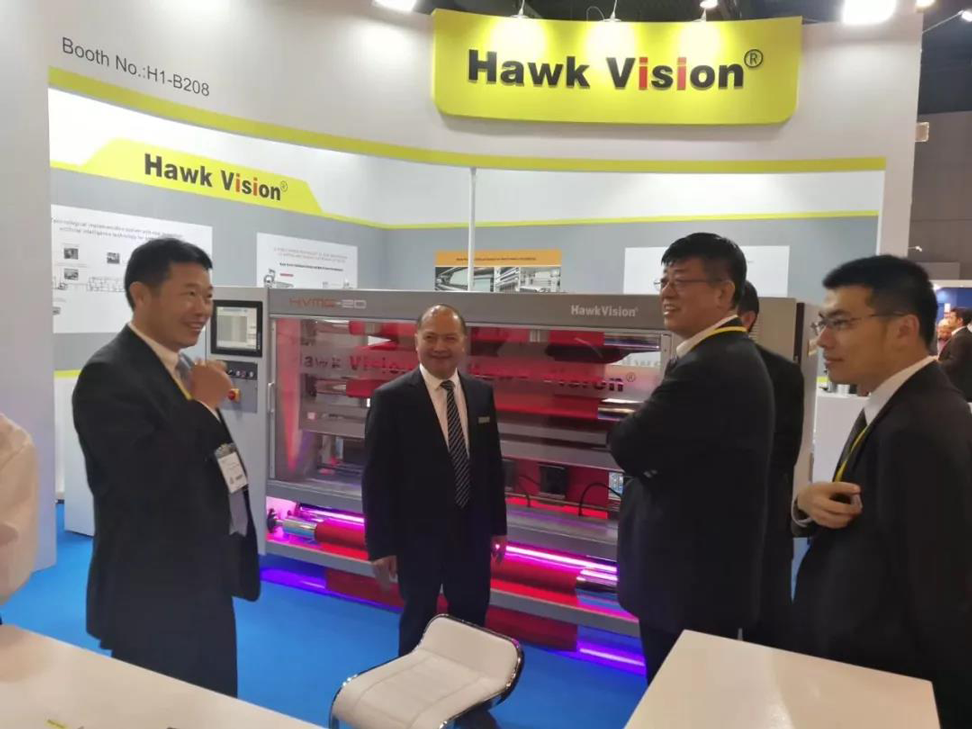

Changzhou Hongda: Passing Chinese-made energy in Europe

Adhering to the concept of “Leading Hawk vision artificial intelligence technology serving the global textile industry!”, Changzhou Hongda has achieved unexpected gains at this exhibition. Gu Ren, the chairman of the company, told the reporter that on the first day of the launch, the customers who came to the booth before the booth had been in constant stream. In front of the Hawk vision® international brand booth, many people expressed surprise and admiration after seeing the smart image whole flower weft. Gu Ren said that we are going to push our products to the world and make the world better understand Chinese manufacturing. “When some customers see the product, ask if we are made in Germany? Is it made in the US? I think that our participation goal has been achieved,” Gu Ren said.

It is understood that at this exhibition, Changzhou Hongda and its sub-brand Hawker Weishi focused on textile printing and dyeing and finishing intelligent control system, and launched a number of textile printing and dyeing intelligent measurement and control products using artificial intelligence technology: Hawk based on artificial intelligence technology. Vision® intelligent image whole flower weft machine and a new generation of artificial intelligence technology setting machine process execution system. These products have been produced and applied in many well-known textile printing and dyeing factories at home and abroad, which has greatly improved the level of intelligence for the enterprise, and saved labor, provided support for the success rate of the products, and was well received by the market and praised by customers.

The Hawk Vision® Intelligent Image Whole Flower Weft Machine is backed by the “HockVision” brand with its strong European technical background and Changzhou’s profound technical research and development strength. It is the first internationally-advanced “full-width scanning whole-wedding technology”. The machine uses a new technology to completely solve the problem of textile flower deformation, weft and weft bending which cannot be corrected and recognized by photoelectric weft. It is suitable for yarn-dyed fabric, printed fabric, jacquard fabric, transfer printing, sanding cloth, Knitted fabrics, denim fabrics, sofa fabrics, curtain fabrics, twill fabrics, heavy fabrics, high-density high-density fabrics, silk-simulated silk chiffons, digital printing sizing, composite processing, and other weaving textiles, breaking photoelectric weft knitting machines and ordinary images The weft-aligning machine has various restrictions on the weaving, texture and thickness of textile fabrics, surpassing the value of photoelectric weft and ordinary image weft, creating a core value for textile enterprises!

The product won the first prize of the “Textile Light” China Textile Industry Federation's Technology Progress Award in 2017, and was recognized as the international leader by the China Textile Industry Federation expert group.

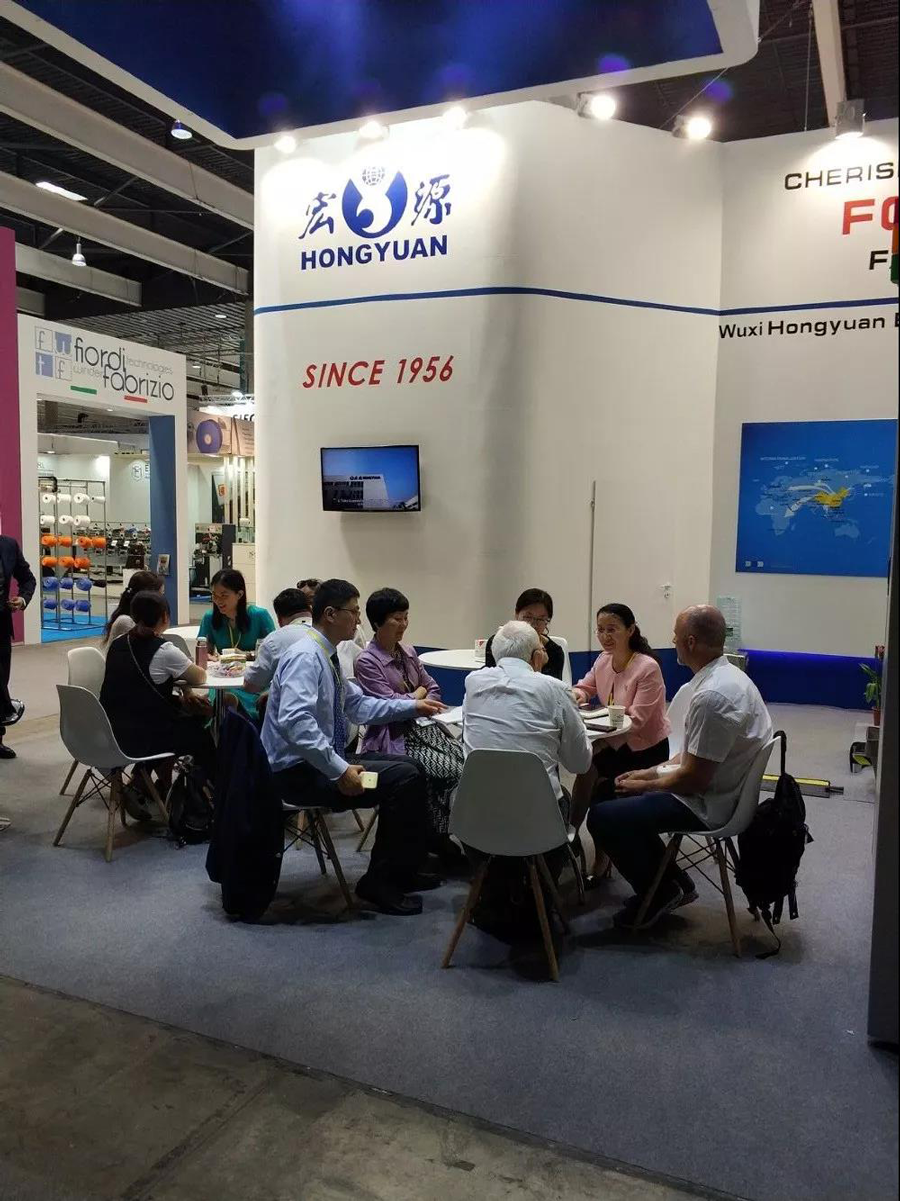

Wuxi Hongyuan: High-speed texturing machine stunning scene

On the second day of the exhibition, Chen Zhihong, general manager of Wuxi Hongyuan, clearly felt the increase in the number of customers. She introduced that in the past two days, she has seen many customers from Iran, Egypt, Vietnam, Pakistan, Turkey and other regions. Some customers were surprised to see the HY-9 automatic drop-height high-speed stretch yarn machine. They didn't even know that China could produce such high-end texturing machine products. Some customers have reached the demand for intent orders through further communication on the spot.

Chen Zhihong introduced that at this exhibition, Wuxi Hongyuan will focus on HY-9 automatic drop high-speed stretch yarn machine, HY-10 multi-spindle high-speed stretch yarn machine, HY-Auto498 automatic doffing roving frame, HY -IDS chemical fiber filament automatic unwinding conveyor system four intelligent high-speed, high-efficiency exhibits.

HY-9 automatic drop high-speed stretch yarn machine has the characteristics of high automation, energy saving and environmental protection, high speed and high efficiency, convenient operation and maintenance. The machine has innovated and developed the automatic spinning head system for spinning and changing. After the spinning reaches a fixed length, it can automatically change the cylinder to realize automatic heading. The single-spindle electronic precision digital winding system realizes the high flexibility, high automation and cost-effective single-spindle digital drive of the texturing machine. The heat box adopts the fully enclosed thermal insulation technology and the new nano-multi-layer thermal insulation material, and the energy saving effect is obvious.

HY-10 multi-spindle high-speed stretch yarn machine is a design concept based on complete functions, energy saving, convenient operation and maintenance, high efficiency, etc., with independent intellectual property rights equipment, to meet the fierce market competition pattern at home and abroad, leading China The market for flower spinning. With a new double-wound structure, a new multi-ingot number technology has been formed. The single section is extended from 24 spindle positions to 48 spindle positions, and the whole machine is at least 10 knots, at least 480 spindles. The machine capacity doubled and the efficiency doubled.

In order to achieve high efficiency, high automation, reduce labor and reduce labor intensity, and meet the needs of high-end customers, Hongyuan has introduced a new type of roving machine that combines spinning and doffing functions - HY-Auto498 automatic doffing roving The machine, its drafting device and the main drive inherit the stable and reliable characteristics of the mature model of Hongyuan. The doffing adopts the external automatic doffing structure to realize the automatic completion from the doffing, changing the tube, making the head and driving. The whole process is about Two minutes.

The HY-IDS chemical fiber filament automatic unwinding conveying system developed by the company is a silk cake post-processing equipment specially designed for the chemical fiber filament production line.

The system can realize the automatic unwinding and conveying function of the cake. Improve the automation level of the process after the production of chemical fiber filaments, improve product quality and reduce labor costs. According to the actual needs, modular combination can be realized to realize the customized auxiliary system for filament production. The system is characterized by high quality, high efficiency and low cost. With international advanced level.

Reprinted from China Textile