01

Top Ten Key Developments in China's Intelligent Manufacturing in 2019

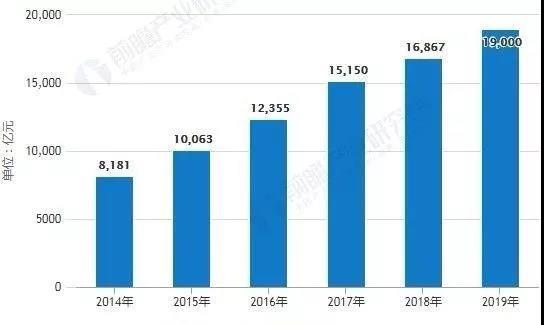

In 2018, driven by supportive government policies and the advancement of intelligent manufacturing, China's intelligent manufacturing industry experienced rapid growth. The market size is projected to reach 19000 billion yuan in 2019. (From an external source)

Intelligent manufacturing is one of the key turning points for the global industrial sector's revival. With the rapid development of 5G, artificial intelligence, and the Internet of Things, intelligent manufacturing has seen its first ray of sunshine after a period of hardship.

According to data, in 2017, the market size of China's intelligent manufacturing industry was 15150 hundred million yuan, with a growth rate of 22.6% , and with in-depth research on technology and more innovative products from various companies and institutions, the market size is expected to reach 19000 hundred million yuan in 2019.

Market Size of China's Intelligent Manufacturing Industry

Data Source: Compiled by the Foresight Industry Research Institute

With the continuous introduction of policies in the intelligent manufacturing field, China's manufacturing industry is gradually transforming towards intelligent manufacturing and beginning to extensively apply related technologies such as cloud computing, big data, and robotics. As one of the main driving forces of China's manufacturing industry, with the continuous introduction of favorable policies, the industry will continue to grow steadily, and its role in China's manufacturing industry will become increasingly important.

From the perspectives of development prospects, technological integration, business models, and production safety,

2019 will see ten major development trends in China's intelligent manufacturing.

Safety production will become paramount.

Industrial core data, key technological patents, and enterprise user data, etc., have become core assets of enterprises as digital assets. As the primary guarantee for production,

safety has always been a major concern for both the government and employees.

When intelligent manufacturing integrates many cutting-edge technologies such as robots and artificial intelligence, accidents that humans can promptly control seem simpler. However, with an increase in equipment, how to effectively manage safety during human-computer interaction is a key issue.

In addition, after the Industrial Internet of Things (IIoT) enters the manufacturing industry, incidents of IIoT data attacks frequently occur, so the security of enterprise equipment, product data, etc., is also particularly important.

Currently, China's data security regulatory system and supervision mechanism are not yet sound, which has to some extent inhibited the pace of enterprise intelligent upgrading. In the future, improving data security throughout its lifecycle and increasing enterprise trust and willingness to use cloud services

02

will become an important basis for Chinese enterprises' intelligent upgrading decisions.

The intelligent manufacturing industry will further expand. Intelligent manufacturing has been gradually deepening its application in the automotive and 3C electronics industries. Once companies recognize that intelligent manufacturing is a crucial direction for achieving "Made in China 2025," digitalization, networking, and intelligence can continuously optimize enterprise output and efficiency,

03

intelligent manufacturing will further penetrate industries such as petrochemicals, textiles, and machinery.

General-purpose technologies may become a breakthrough for AI+. With the vigorous development of customized flexible manufacturing and multi-scenario production, general-purpose technologies cannot meet production needs.

For AI to empower traditional industries, it can easily solve these needs.

04

With the accumulation of big data, enterprises can use AI to achieve rapid transformation in professional scenarios, truly transforming manufacturing into "intelligent" manufacturing.

Digital twin technology may rise.

In 2018, the automotive industry was relatively sluggish, and did not experience the usual "golden September and silver October." Objectively speaking, the cost of buying and maintaining a car is high.

Digital twin technology will be the first choice for enterprises' digital upgrading and intelligent factory construction. Automakers can use this technology to solve problems such as complex production processes and resource waste that lead to high costs during the R&D process, creating digital models at lower costs.

By reducing costs, the automotive industry's sales next year are promising. At the same time, introducing digital twin technology in the 3C field can also drive industry development.

05

It is expected that by 2020, at least 50% of manufacturers with annual revenue exceeding 1 billion yuan will launch at least one digital twin project for their products or assets.

Creating a precise big data closed loop. In recent years, industrial big data has begun to be valued by enterprises. Using big data can uncover the hidden customer value, helping enterprises transform their time-limited customer needs, production systems, business models, and decision-making models.

Big data can help enterprises go from 0 to 1, then from 1 to N, and from N to 1 (personalization).

06

To achieve this model, enterprises need to build a precise data flow closed loop from collection, analysis, transformation, and feedback.

More internet companies are entering the intelligent manufacturing field.

Internet companies entering the industrial field, i.e., "Internet + intelligent manufacturing," has achieved initial success. Alibaba Cloud and Siemens have partnered to officially enter the Industrial Internet of Things, while Baidu's smart factory and JD.com's smart supply chain are also building their own intelligent manufacturing industries.

07

Internet companies have long-term data accumulation and technological advantages. After entering the industrial field, they can bring more technological application scenarios to traditional manufacturing enterprises and accelerate the transformation of enterprises' intelligent manufacturing.

User needs will guide enterprise transformation. The industrial development process is shifting from enterprises' product-driven user needs to user needs leading enterprise production, intelligent manufacturing will change traditional manufacturing from reducing costs and increasing efficiency in the production process to providing high value-added derivative services,

08

from providing intelligent products to intelligent services to achieve increased added value.

Industry-level industrial internet platforms will be the first to explore market-oriented business models.

Due to the limited depth of general-purpose industry platforms, the market supply and demand do not match, resulting in a weak willingness of enterprises to use cloud services and the lack of mature market-oriented models.

09

Industry-level industrial internet platforms, with their dual characteristics of focus and universality, can meet the different needs of various industries in intelligent manufacturing and are expected to be the first to explore feasible market-oriented business models.

Focus on intelligent manufacturing solutions and other sub-sectors. Because China's intelligent manufacturing started relatively late, talent cultivation and financial pressure are the biggest problems faced by enterprises,

If small and medium-sized enterprises delve into specific areas such as intelligent manufacturing systems, they are expected to become unicorns.

10

The ultra-high value-added manufacturing sector will be the optimal entry point for additive manufacturing in the industrial field.

Additive manufacturing technology applications in desktop-level applications and simple, large-scale processes do not have a cost advantage. However, in areas such as the manufacturing of ultra-high value-added, ultra-large customized single products represented by engines, wind turbine blades, and submarine propellers, it may bring opportunities for additive manufacturing in the industrial field in 2019.

Related News

Tel:+86-519-88856666

Fax:+86-519-85158666

Email:czhongda@czhongda.com.cn

Company Address: No. 220, Taishan Road, High-tech Zone, Changzhou, Jiangsu Province, China

Tiktok

Official Account

Copyright © Changzhou Hongda Intelligence Technology Co., Ltd.