The Difficulties of MES Implementation (2) - Implementation Chapter!

Let experienced consultants tell you about the difficulties of MES implementation. (Forward)

This article is a series of articles on MES implementation the second part; the first part, 《The Difficulty of MES Implementation Lies First in Selection》 can be reviewed by clicking. The author explains the various issues that need to be considered during MES selection. In summary, there are the following points:

① Establish a good MES selection team

First, top management must participate and give sufficient attention. It is best for the manufacturing director to personally lead the team, with relevant personnel from various business units (planning, warehouse, production, process, quality, equipment, etc.) tracking the entire process, and with the support of senior industry consultants. Building a three-level promotion mechanism of "leadership"-"execution"-"consultant" ensures the smooth and successful selection of MES.

② Cultivate internal strength, clarify needs

Streamline the relationship of your own manufacturing process, deepen your understanding of MES, and lay the foundation for MES selection and implementation. This can be carried out in three steps: ① Build a lean manufacturing process; ② Understand the role of MES; ③ Know what you want. In summary, it is the three-character mantra - "Manage business, improve cognition, clarify needs".

③ Develop a reasonable MES implementation plan

Don't be greedy, don't seek quick wins. Proceed with the MES implementation step by step in a down-to-earth manner.

④ Understand MES suppliers and products

Through the "four observations" of industry, products, teams, and POC, thoroughly understand the suppliers and products from the inside out. Knowing yourself and your enemy, you can win every battle.

After selection, the next difficulty lies in implementation.

The implementation of MES involves multiple departments such as production, process, planning, quality, equipment, and warehouse, with complex relationships and coupled business processes, and diverse departmental needs that are difficult to reconcile. Since I started working in the MES industry in 2003, my first contact was with implementation, and I am well aware of its complexity, hence the impulse to write this article.

As the second part of this series of articles, it mainly starts from the author's project management and implementation experience, and explains the difficulties and key points in the implementation process from the aspects of MES implementation motivation, MES implementation and team, MES standard TO-BE process construction, and basic data standardization scheme writing, to escort the smooth implementation of MES projects.

Clarify goals, establish the correct MES implementation motivation

Before discussing MES project implementation, we can first look at why customer enterprises want to implement MES, and understand the motivation and purpose of customer enterprises implementing MES. From the author's project experience, the main motivations for customer enterprises to implement MES are as follows:

1) Manufacturing enterprises are OEM in nature, and they propose the need for MES to meet customer requirements;

2) Enterprises propose the need for MES in response to national intelligent manufacturing policies;

3) Comparison within the group or between enterprises, proposing the need for MES;

4) The group forces subsidiaries to implement MES, proposing the need for MES;

5) The current connection, management, and manufacturing business processes between departments of manufacturing enterprises are obviously unsuitable for enterprise development, proposing the need for MES.

Among them, the first four motivations are prone to failure because they violate the principles of MES implementation. MES is a natural need after workshop automation, workshop business management, and inter-departmental collaboration have developed to a certain stage. At this time, the original workshop management methods and inter-departmental collaboration methods can no longer meet the requirements of enterprise development, and it is necessary to further deepen the control of workshop data, information, processes, and collaboration. This is the main reason for promoting enterprises to implement MES, and it determines the trend of enterprises implementing MES. The first four motivations either have limited duration or limited driving force. Once they encounter resistance (such as user non-support, unmanageable processes, changes in OEM customer requirements, etc.), it is difficult to push enterprises to continue implementing MES, and it is easy to fail.

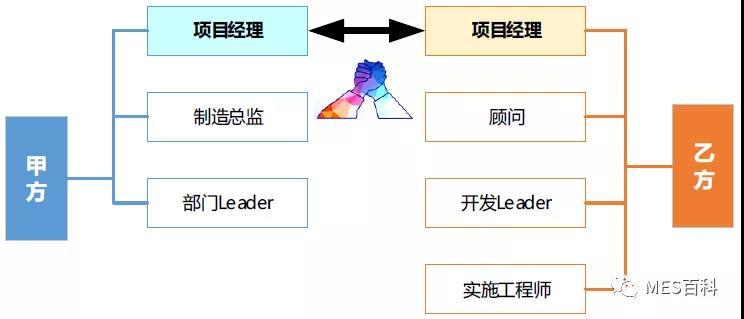

Build a team, clarify the responsibilities of both parties, and set KPIs

MES implementation is a matter for both parties. Both parties need to build a team and clarify the responsibilities of the project manager and the KPI assessment methods. The roles of the client's team mainly include the manufacturing director, project manager, and leaders of various user departments; the supplier's project team includes the project manager, consultant, development leader, and implementation engineer.

The project manager in the project team is very crucial and needs to be fully involved, especially the client's project manager, who must ensure full participation in the early stages. Since most of the client's project managers hold multiple positions, have many tasks, and have a high workload, the hardship is self-evident. Therefore, it is necessary to formulate appropriate KPI assessment methods and reward mechanisms to, on the one hand, stimulate the work enthusiasm of the project manager and the project team, and on the other hand, assess the project progress and identify problems in a timely manner. I once served as an MES implementation consultant in a state-owned enterprise with the Chinese character, and during the project implementation, due to the formulation of a detailed and effective KPI assessment plan, the project manager devoted himself to the MES project during the day and worked overtime at night to complete his own work. Finally, this project manager was promoted to director of the manufacturing department due to his outstanding performance and completed the project on time and with high quality.

Arrange business, build standard TO-BE processes for manufacturing enterprises

Achieve lean and collaborative manufacturing

3.1. Why build TO-BE processes

The purpose of building TO-BE processes is to help enterprises achieve lean manufacturing and collaborative manufacturing. Generally, in MES projects, after the selection is completed and the contract is signed with the supplier, both parties will simultaneously sign the SOW (Statement of Work). However, the scope of functions defined in the SOW is only a simple description of the MES function points, without describing the basic data or listing the business processes. Relying solely on this SOW is not enough to start the MES implementation. Even if it is implemented, since MES involves collaboration between different departments such as planning, warehouse, process, production, quality, and equipment, without standard TO-BE processes for planning, the results are predictable. Here are two examples:

1) Material delivery

Material delivery involves collaboration between the warehouse and production. How to deliver materials, how much to deliver each time, and according to what standards to deliver all involve the operational convenience between departments and the consideration of interests between departments. The production department does not want one-time delivery; I need as much as I need, otherwise, materials piled up on the production line are easily lost; the warehouse department hopes for convenience, one-time delivery, to minimize delivery workload. This requires prior discussion and planning of the delivery process.

2) ECN Engineering Change Notice

ECN involves the coordination of planning, warehousing, and production. For example, when the M-BOM changes, should the currently in-progress work orders continue or be closed? How to close them? How are materials returned to the warehouse after closure, and how are finished products handled? These also need to be discussed and planned. The workflow of ECN changes is also a problem that MES needs to solve. Without this process, how can MES implementation be discussed?

So who determines this coordination? It is determined by the standard TO-BE process. The standard TO-BE process consists of a series of sub-processes. Taking the electronics industry as an example, it includes five sub-processes:

The TO-BE process clearly depicts what is intended to be done in the future. By constructing the TO-BE process, the business processes of different departments such as planning, warehousing, production, quality, technology, and equipment are clarified and defined, and the methods and standards for inter-departmental collaborative manufacturing are defined, thus forming an MES requirement plan and obtaining a standardized basic data solution. With these, MES can truly begin implementation. Otherwise, as mentioned in the example, it is easy to fail to implement.

3.2. How to build a standard TO-BE process

First, the TO-BE process requires a team to build. It is jointly promoted by professional consultants, manufacturing directors, quality managers, process managers, planning managers, and warehouse managers based on the actual situation of the enterprise, and is derived after fully sorting out the enterprise's manufacturing execution business and collaborative manufacturing relationships. If necessary, a separate consulting project can be conducted to invite industry experts to assist in the sorting. At the beginning of 2014, the author worked on an MES project for a certain factory, and the client company selected a Korean MES product. When constructing the standard TO-BE process, the author, Korean MES consultant experts, the manufacturing director, quality director, and process department of the client company spent a total of 3 months building all the standard TO-BE processes, laying a good foundation for the subsequent successful implementation of MES.

Building a TO-BE process oriented towards the collaboration of various business departments generally includes multiple business-related topics. Due to space limitations, only a brief description can be provided here. The author still describes this process based on practical experience. The following takes the electronics assembly industry as an example:

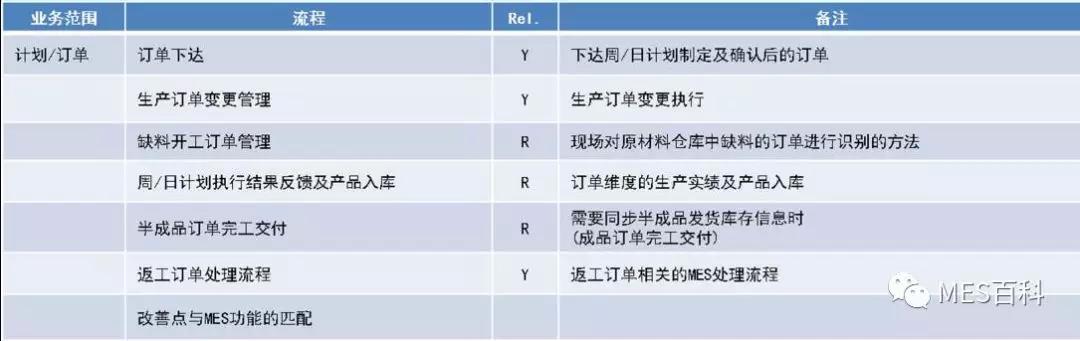

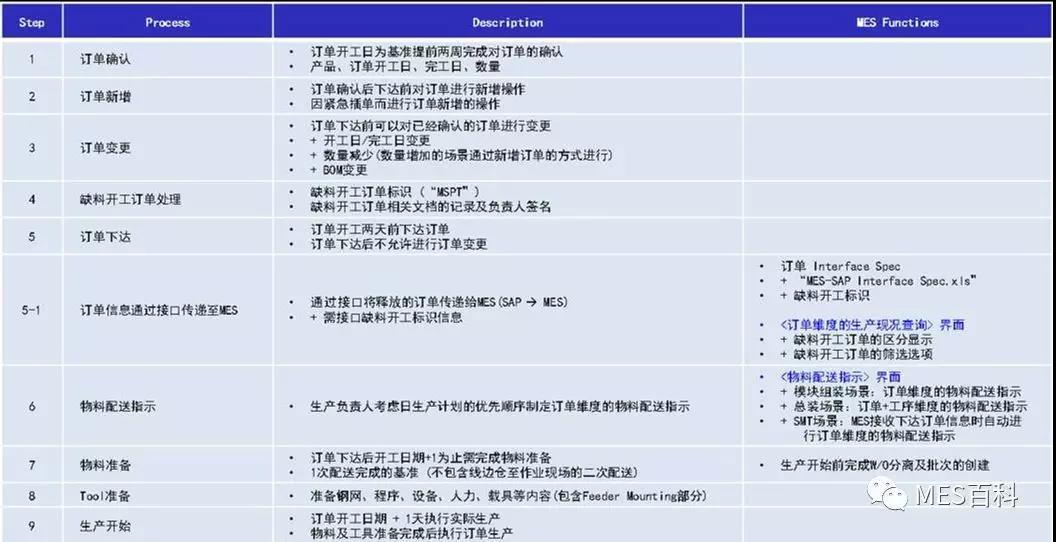

1) TO-BE Process Design - Order Process

The Order Process details the relevant business of shop floor work order processing, including docking with the ERP system, work order issuance, work order execution, and reporting.

The key points of the order process are: work order release, production order change management, and shortage start order management.

① Work order release. Clearly describe how the shop floor obtains work orders, how work instructions are issued, which departments and systems are involved, and how to roll back if problems occur.

② Production order change management. Clearly describe the approval process for order changes and the actions the shop floor needs to take when changing orders.

③ Shortage start order management. For orders that start with shortages, clearly describe how to approve, how to start, how to replenish materials, and how to change to a regular order after replenishment.

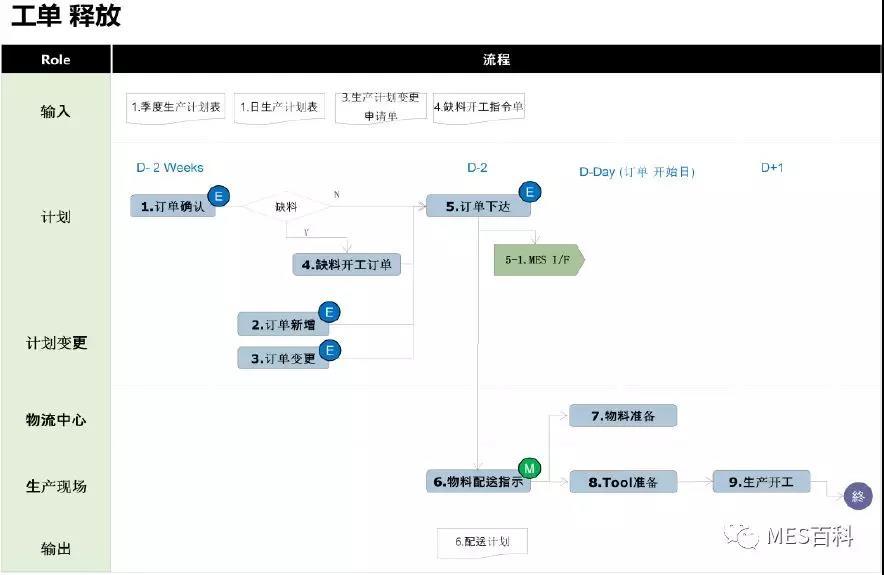

Taking work order release as an example, the construction process of the standard TO-BE process is as follows:

① Preparation: Clarify the relevant basic data of work order management;

② Define the input and output of the TO-BE process;

③ Draw the business process of work order processing, paying attention to pointing out the various departments, work content, and interrelationships involved in the business process;

④ Based on the standard TO-BE process, break down the system function details.

Figure: Work order release: The process of work instructions and preparation for production orders with confirmed plans

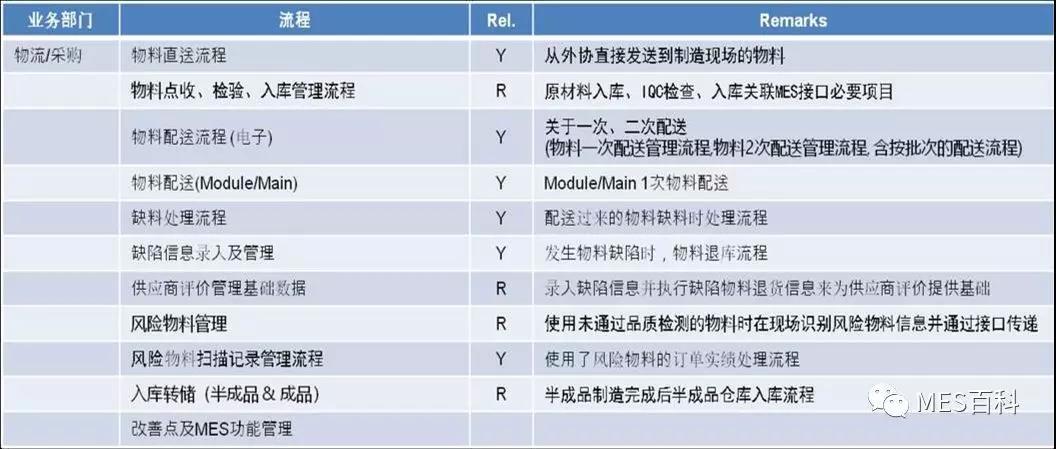

2) TO-BE Process Design - Material Management Process

The Material Management Process details the relevant business of shop floor material distribution and consumption, including material warehousing, IQC and defect records, material distribution, deduction, and return.

The key points of the material management process are: material distribution, material receiving, inspection, warehousing, and material distribution.

① Material distribution. Clearly describe how to form a material procurement plan, how to generate a notice for outsourcing material distribution, IQC and defect records, how to warehouse, and how to distribute to the line-side warehouse.

② Material receiving, inspection, and warehousing management process. Clearly describe how to count materials, handle IQC and non-conforming products, replenish, warehouse, secondary packaging, and internal label management.

③ Material distribution process. Clearly describe the process of generating picking lists based on orders, material distribution, and line-side warehouse receiving.

3) TO-BE Process Design - Quality Process

The Quality Process details the relevant business of shop floor quality management, including inspection, exception management, and quality traceability.

The key points of the quality process are: initial inspection & in-process inspection & final inspection.

① Initial inspection & in-process inspection & final inspection. Clearly describe how the shop floor selects work orders for inspection, handles non-conforming products, and controls QC certificates.

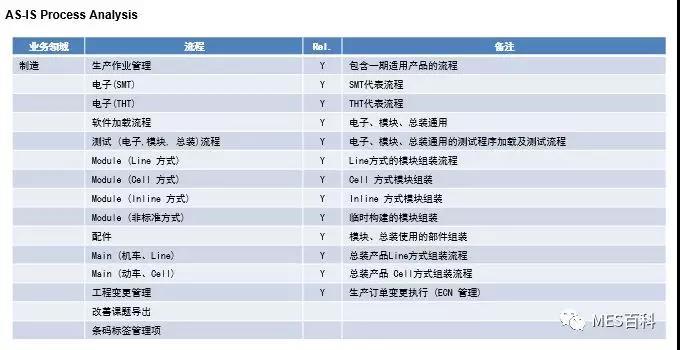

4) TO-BE Process Design - Manufacture Process

The Manufacture Process details the shop floor manufacturing process, sorting out the system operation process that conforms to the on-site business and the working environment of the operators, including operation execution, process control, data collection, shift management, process/formula management, etc.

The key points of the manufacturing process are: operation execution and data collection.

① Operation execution. Clearly describe the process of the shop floor executing work orders, how to pass stations, how to lock, and how to batch and combine batches. Note that business must be conducted through the system.

② Data collection. Clearly describe the process of collecting engineering data on the shop floor, which data of which equipment to collect, the collection frequency, the collection method, and the data processing business process.

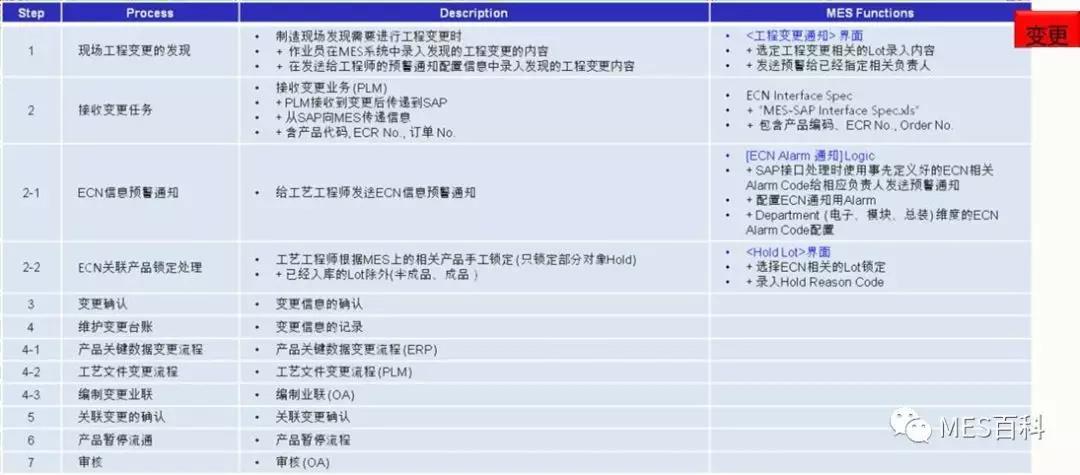

5) TO-BE Process Design – ECN Process

The ECN Process details the relevant business of how to handle engineering changes, including change approval, change release and notification, and change execution.

Figure: Engineering Change Management Engineering Change Execution (ECN Management)

The key points of the engineering change management process are: order change processing.

① Order change processing. Clearly describe how to handle work orders and materials when changes occur.

process

Export suitable and effective MES requirements

The greatest significance of building a standard TO-BE process lies in using this process to derive a suitable MES requirement plan that closely aligns with the company's needs. Through TO-BE process analysis, combined with the SOW signed during contract signing, the manufacturing director, professional consultant, and project managers from both parties can build an effective, suitable, and professional requirement document based on the company's production characteristics and business needs. Requirements should not aim for comprehensiveness; some functions, even if implemented, may not be truly usable. It's crucial to start from the TO-BE process and identify truly suitable and effective requirements. Unrealistic requirements should be avoided; those that are not true MES requirements should also be avoided; Requirements that are achievable but delay progress and fail to meet the project's deadline should also be avoided. Once the requirements are defined, MES implementation will have a solid foundation, and risks can be accurately predicted.

A well-constructed MES requirement plan must be signed and confirmed by the responsible parties from both sides to ensure its stability, persistence, and reliability, preventing interference from external factors. A stable MES requirement plan facilitates project progress and reduces implementation risks.

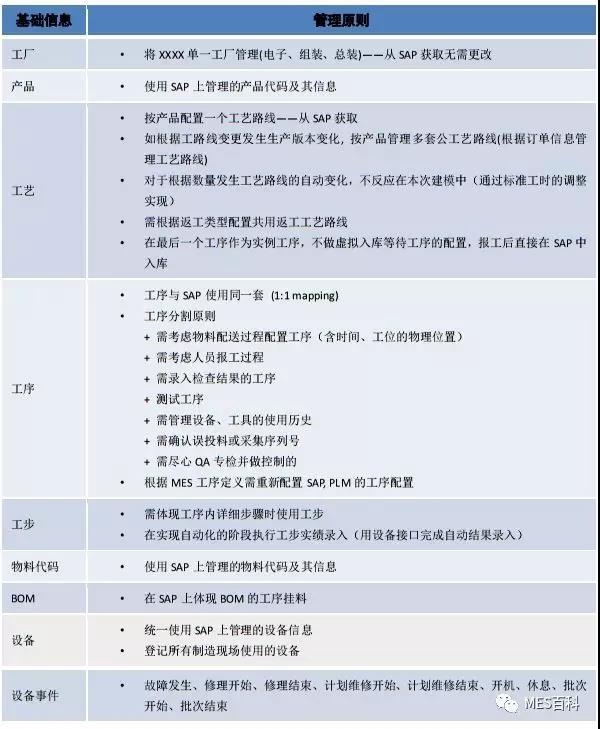

Define Data

Organize and Standardize Basic Data Summary Plan

Based on the TO-BE process and requirement plan, organize and determine the basic data standardization summary plan. After the TO-BE process analysis, client companies often find that MES basic data, such as workshops, processes, products, materials, BOM, and Defect Code, either exist in ERP or PLM but lack sufficient granularity or are simply nonexistent. In such cases, it's necessary to consider organizing basic data from its sources. Data sources include existing systems like ERP, PLM, and CAPP, as well as historical archives. For different basic data, use different standardization plans based on the company's specific situation to derive the most effective basic data. A basic data standardization plan is shown in the table below.

Concluding Remarks

Since 2003, I have implemented MES in various industries, including electronic assembly, automotive parts, machining, semiconductor packaging and testing, and medical devices. Some projects were successful, some failed, and some took many detours. I want to say that there are many reasons for MES failures, including business, processes, collaboration, functions, and requirements... all of which can lead to MES implementation failure. However, the failure of any project is not one-sided; ultimately, it is due to the combined reasons of both parties. I hope that the experiences summarized in this article will provide some inspiration and help to both the client and the vendor, fostering mutual understanding and cooperation to successfully implement MES projects.

Related News

Tel:+86-519-88856666

Fax:+86-519-85158666

Email:czhongda@czhongda.com.cn

Company Address: No. 220, Taishan Road, High-tech Zone, Changzhou, Jiangsu Province, China

Tiktok

Official Account

Copyright © Changzhou Hongda Intelligence Technology Co., Ltd.