Tackling hardcore technologies, Changzhou Hongda Wisdom Technology has a bumper harvest season, winning numerous awards!

Currently, "green, circular, and digital" is the development direction of the textile industry. As an important support for the textile industry, the textile machinery industry is promoting the transformation and upgrading of the industry towards digitalization, intelligence, greening, and integration, achieving higher-level development of the industry.

Currently, "green, circular, and digital" is the development direction of the textile industry. As an important support for the textile industry, the textile machinery industry is promoting the transformation and upgrading of the industry towards digitalization, intelligence, greening, and integration, achieving higher-level development of the industry.

High-quality development of the industry cannot be separated from the technological support of enterprises. Changzhou Hongda Intelligence Technology Co., Ltd. mainly engages in the research and manufacturing of intelligent information management and control system products for textile printing and dyeing production processes, and is known as the "printing and dyeing electrical expert" in the industry. The company has strong independent innovation capabilities and internationally leading technologies, with core advantages in deeply understanding and researching intelligent manufacturing in the industry. It masters cutting-edge machine vision technology, artificial intelligence technology, digital twins, and automation technology, leading the development of intelligent manufacturing in the textile printing and dyeing industry, and has become an industry benchmark.

It is understood that Changzhou Hongda Intelligent Technology has made significant breakthroughs in the digital transformation and sustainable development of the textile printing and dyeing industry, thanks to its strong independent innovation capabilities and internationally leading technologies. Currently, the company has achieved a series of remarkable achievements, including the Ministry of Industry and Information Technology's "two-integration" pilot demonstration enterprise, the National Printing and Dyeing Digital System Technology Research and Development Center, Jiangsu Province's specialized and new small and medium-sized enterprises, and the China Association for Science and Technology's "Science and Technology Innovation China" emerging enterprises.

Recently, Changzhou Hongda Intelligent Technology has achieved remarkable results with multiple products and technologies winning numerous awards:

The "Key Technologies and Industrialization of the New Generation of Green Digital Finishing Machine Intelligent System" project has been appraised by the China Textile Industry Federation and has reached the "internationally advanced" level.

The "Fabric Image Whole Flower and Whole Weft Machine Based on Artificial Intelligence Technology" has been successfully selected for the 2023 "Recommended Catalog of Advanced Technologies and Equipment in China's Knitting Industry".

The HV intelligent finishing process execution system has been included in the sixteenth batch of the Recommended Catalog of Energy-Saving and Emission-Reduction Advanced Technologies in China's Printing and Dyeing Industry.

The "Application Typical Case of Digital Finishing Machine Intelligent System for Printing and Dyeing" was shortlisted for the 2023 Industrial and Information Technology Quality Improvement Typical Cases released by the Ministry of Industry and Information Technology.

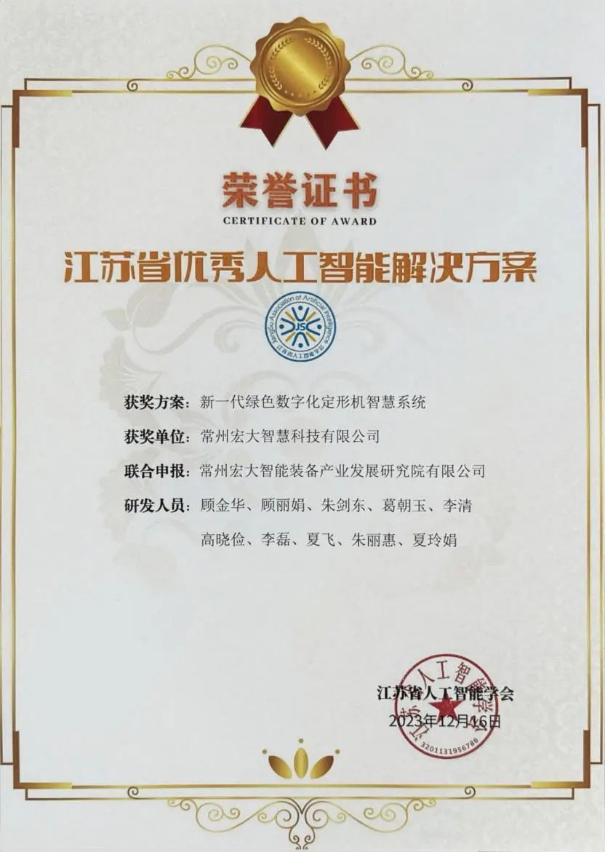

The "New Generation Green Digital Finishing Machine Intelligent System" has won the honorary certificate of "Excellent Artificial Intelligence Solution of Jiangsu Province".

Won the "2023 China Textile Industry Federation Product Development Contribution Award".

Shortlisted for the 2023 Jiangsu Provincial Artificial Intelligence Society Science and Technology Award (Solution) list.

...

When talking about future development, Gu Ren, chairman of Changzhou Hongda Intelligent Technology, said that Changzhou Hongda has always been committed to providing comprehensive and high-quality intelligent manufacturing solutions for the textile printing and dyeing industry. In the future, it will continue to focus on the digital transformation of the textile industry, continuously deepen industry-academia-research cooperation, and strengthen scientific and technological innovation and talent cultivation. At the same time, the company will also actively plan to establish a textile equipment digital research center (platform) to promote the high-quality development of "process digitalization" and "equipment intelligence" in the textile industry.

Technological innovation improves product quality

Recently, the Ministry of Industry and Information Technology released the 2023 annual public announcement of typical cases of industrial and information technology quality improvement. A total of 129 enterprises nationwide were shortlisted, including 3 textile enterprises, among which is Changzhou Hongda Intelligence Technology Co., Ltd.'s "Typical Application Case of Digital Finishing Machine Intelligent System for Printing and Dyeing".

It is understood that in order to enhance the industrial and information technology quality management capabilities, promote the application of quality technology innovation, improve the reliability level of products, and timely discover, summarize, and promote a batch of advanced experiences with strong demonstration effects, the Ministry of Industry and Information Technology organized the selection of typical cases of industrial and information technology quality improvement in 2023, including quality management capabilities, quality technology innovation applications, and reliability improvement, covering 12 directions in three aspects.

Changzhou Hongda Intelligence Technology Co., Ltd.'s case focuses on quality technology innovation applications—quality control. It applies digital technology to carry out full-process online quality monitoring, diagnosis, and optimization, implements key process intelligent analysis, precise control, remote monitoring of equipment, and intelligent maintenance, achieving digital control, networked collaboration, and intelligent management of the manufacturing process, continuously enhancing the quality control level of the production process, and improving the reliability, consistency, and stability of product manufacturing solutions. In the textile printing and dyeing production process, Changzhou Hongda's innovative research and development is not limited to a single process, but is based on the transformation of printing and dyeing factories' needs for intelligent and digital equipment, carrying out systematic industrial innovation. Changzhou Hongda builds an intelligent finishing machine system based on artificial intelligence technology to solve the problem of easy deviation in manual operation, realizing digital production from the source and building a digital manufacturing full industrial chain.

Artificial intelligence technology improves weaving efficiency

On December 16, the 6th Jiangsu Artificial Intelligence Conference was held in Nanjing, Jiangsu Province. Changzhou Hongda Intelligence Technology Co., Ltd.'s "New Generation Green Digital Finishing Machine Intelligent System" won the honorary certificate of "Excellent Artificial Intelligence Solution of Jiangsu Province".

The "New Generation Green Digital Finishing Machine Intelligent System" developed by Changzhou Hongda adopts advanced intelligent sensing technology to realize online detection of key process parameters and quality of textiles. It integrates industrial internet and artificial intelligence technology to achieve intelligent control of finishing processes and production, automatically optimizing printing and dyeing process parameters, predicting production defects and quality problems, and making intelligent adjustments, thereby effectively improving the weaving efficiency of the printing and dyeing industry, improving the quality of fabrics, reducing energy consumption, making the production and management of intelligent printing and dyeing factories achieve a qualitative leap, and achieving energy saving, emission reduction, and green and low-carbon production.

Focus on product R&D

Build industry leadership

On December 19, the 2023 China Textile Innovation Annual Conference held the 2023 China Textile Industry Federation Product Development Contribution Award Ceremony. Changzhou Hongda Intelligence Technology Co., Ltd. was among the winners.

In order to implement the "14th Five-Year Plan" for the textile industry, strengthen the supporting and leading role of scientific and technological innovation, fashion creativity, and green development in textile product development, encourage enterprises to build high-quality product development management systems, promote social responsibility construction and sustainable development, and establish a pioneering image of innovation in product development management in the Chinese textile industry, the China Textile Industry Federation recently launched the 2023 "China Textile Industry Federation Product Development Contribution Award/Promotion Award" evaluation activities throughout the industry.

Changzhou Hongda Intelligence Technology Co., Ltd. won the 2023 "China Textile Industry Federation Product Development Contribution Award".

For 35 years, Changzhou Hongda Intelligent Technology has always adhered to innovation and taken the revitalization of national industries as its responsibility. Mastering cutting-edge machine vision technology, artificial intelligence technology, digital twins, and automation technology, it possesses strong independent innovation capabilities and internationally leading technologies, leading the development of intelligent manufacturing in the textile printing and dyeing industry.

New product launch

Breakthrough in R&D innovation

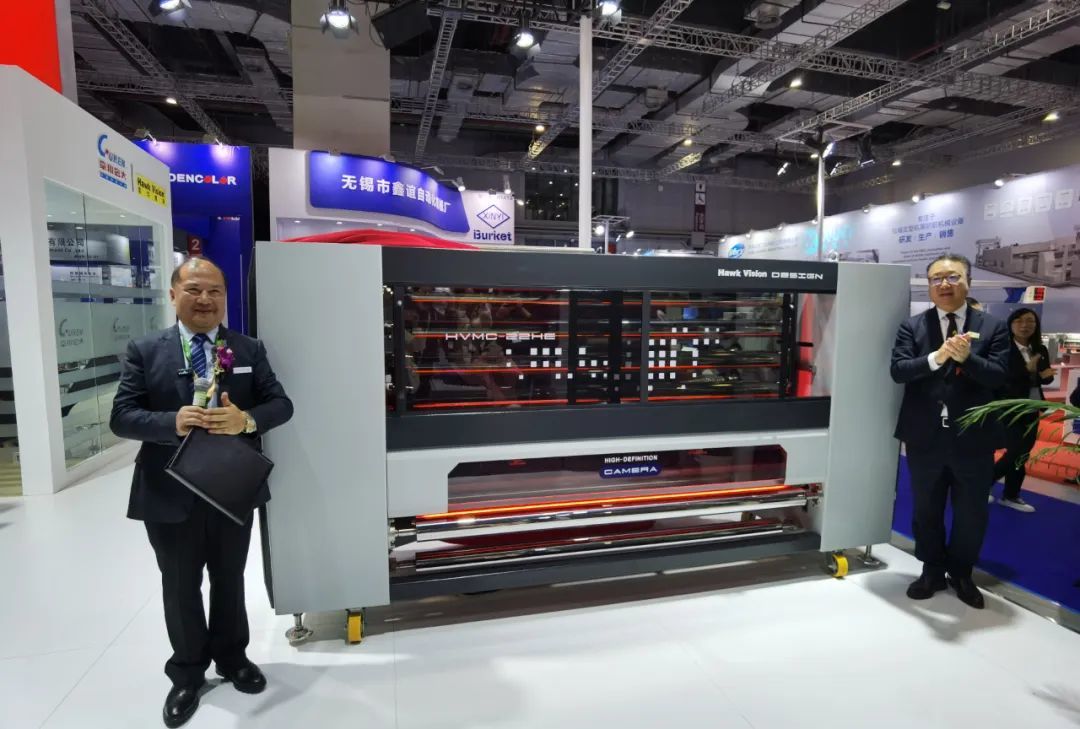

Recently, on the opening day of the 2022 China International Textile Machinery Exhibition and ITMA Asia, Changzhou Hongda Intelligent Technology held a global new product launch conference, launching new products such as the HVMC-HE intelligent image weft inserting machine and the HV-GM200 fabric intelligent online weight detection instrument.

For 35 years, Changzhou Hongda has been committed to independent innovation and continuous progress, supporting the intelligent development of the textile printing and dyeing industry. Promoting high-quality and sustainable development in the industry has always been the driving force behind our commitment to independent innovation. We have achieved remarkable results in the field of intelligent manufacturing for textile printing and dyeing, winning numerous important national awards." Changzhou Hongda Intelligence Technology Co., Ltd. Chairman Gu Ren stated that through continuous efforts, we have once again achieved unprecedented breakthroughs, successfully developing the world's first intelligent online fabric weight detection instrument and the HE series intelligent image weft insertion machine with the latest AI technology. The intelligent online fabric weight detection instrument solves the industry's problem of intelligent online detection of fabric weight, replacing manual marking, greatly reducing fabric waste, and improving product quality.

Gu Ren emphasized that the HE series intelligent image weft insertion machine uses innovative full-width scanning and detection technology for weft deformation and artificial intelligence deep learning technology. It is the company's new generation of image weft insertion machine with the latest technology, following the intelligent image warp and weft insertion machine! These two products integrate years of technological accumulation and innovative spirit, filling an international gap and greatly improving the industry's intelligent level, providing support for the high-quality and sustainable development of the industry.

The HV-GM200 intelligent online fabric weight detection instrument successfully solves the industry problem of intelligent online detection of fabric weight, replacing manual marking, greatly reducing fabric waste, and improving product quality. This product can accurately measure the actual weight of products during production in real time; ensuring product stability and improving product quality; greatly reducing fabric waste during production; the instrument is connected to the density detection overfeeding system to directly build a closed loop to achieve target weight control; it can achieve real-time, continuous, online recording and storage of fabric weight and historical data query, representing a groundbreaking technological breakthrough.

The HVMC-HE intelligent image weft insertion machine has multiple independent intellectual property rights. It uses innovative full-width scanning and detection technology for weft deformation and artificial intelligence deep learning technology. It is a new generation of products with the latest technology launched by the company following the intelligent image warp and weft insertion machine.

The successful development of these two products integrates Changzhou Hongda's years of technological accumulation and demonstrates its spirit of continuous innovation. They fill an international gap, greatly improving the industry's intelligent level and providing strong support for the high-quality and sustainable development of the industry.

Related News

Tel:+86-519-88856666

Fax:+86-519-85158666

Email:czhongda@czhongda.com.cn

Company Address: No. 220, Taishan Road, High-tech Zone, Changzhou, Jiangsu Province, China

Tiktok

Official Account

Copyright © Changzhou Hongda Intelligence Technology Co., Ltd.