Glorious Past, Continued Brilliance - A national enterprise committed to high-quality development led by technology for the future

With the advancement of intelligent manufacturing, the demand for intelligent testing equipment is increasing, with new technologies and products emerging, and the industry showing rapid development. However, overall, China's intelligent testing equipment industry still faces problems such as a weak technological foundation, insufficient innovation capabilities, insufficient high-end supply, an imperfect industrial system, and an underdeveloped application ecosystem. This has become a key bottleneck and important constraint to the in-depth development of intelligent manufacturing, and there is an urgent need to improve supply capabilities and levels.

Changzhou Hongda Intelligence Technology Co., Ltd. (hereinafter referred to as "Changzhou Hongda") is a leading enterprise in the field of online inspection equipment and intelligent digital production lines for the textile and dyeing industry! It possesses strong independent innovation capabilities and internationally leading technologies, with core advantages in its deep understanding and research of intelligent manufacturing in the industry. It masters cutting-edge machine vision technology, artificial intelligence technology, digital twin technology, and automation technology, leading the development of intelligent manufacturing in the textile and dyeing industry and has become an industry benchmark!

Changzhou Hongda Intelligence Technology Co., Ltd.

Under the leadership of Chairman Gu Ren and the R&D team, founded in 1988, Changzhou Hongda Intelligence Technology Co., Ltd., as one of the largest and most powerful professional enterprises in China engaged in the research and manufacturing of intelligent online monitoring and intelligent information management and control systems for textile and dyeing production processes, is a national high-tech enterprise, a national Ministry of Industry and Information Technology "two-integration" pilot demonstration enterprise, a national dyeing digital system technology R&D center, a national Ministry of Industry and Information Technology energy-saving and emission-reduction technology recommended enterprise, and a "specialized, refined, and new" enterprise in the Chinese textile industry. It adheres to using technology to create value for its customers and has won numerous accolades:

In 2023, the "Key Technologies and Industrialization of the New Generation Green Digital Shaping Machine Intelligent System" project independently developed by Changzhou Hongda was appraised by the China Textile Industry Federation and reached "Internationally Advanced" level; the "Fabric Image Whole Flower and Whole Weft Machine based on Artificial Intelligence Technology" was successfully selected for the 2023 "Recommended Catalog of Advanced Technologies and Equipment in China's Knitting Industry" ; meanwhile, the HV intelligent shaping process execution system was included in the Sixteenth Batch of Recommended Catalog of Advanced Energy-Saving and Emission-Reduction Technologies in China's Dyeing Industry . "List of Typical Cases of Quality Improvement in Industry and Information Technology in 2023" ; and won the 2023 China Textile Industry Federation "Product Development Contribution Award" ; and was shortlisted for the 2023 Jiangsu Provincial Artificial Intelligence Society Science and Technology Award (Solution) list.

In 2022, Changzhou Hongda won the national Ministry of Industry and Information Technology Product Green Design Demonstration Enterprise 、 "Science and Technology China" Emerging Enterprise, "Science and Technology China" List Leading Technology , won the Jiangsu Provincial "Specialized, Refined, and New" Enterprise, China Textile Industry "Specialized, Refined, and New" Enterprise, Chairman Gu Ren was awarded the "Fifth Changzhou Excellent Inventor Award", the "Digital System Strategic Emerging Industry Standardization Pilot Project for Dyeing Equipment" project was selected for the 2022 Jiangsu Provincial Strategic Emerging Industry and Service Industry Standardization Pilot Project, and received the "New Technology Demonstration Award" awarded by the National Knitting Science and Technology Information Center.

In 2021, Changzhou Hongda was elected "President Unit of the Dyeing Machinery Branch of the China Textile Machinery Association", Hawk Vision® intelligent image whole flower and whole weft machine technology was identified as internationally leading, and won the China Textile Federation Science and Technology Progress First Prize , 2021 "Science and Technology China" leading technology.

In 2020, Changzhou Hongda's "invention patent for fabric automatic whole flower method based on machine vision" won the 2020 China Patent Excellent Award , 2019 China Textile Industry Federation Patent Gold Award 。

In 2019, Changzhou Hongda won the "National Ministry of Industry and Information Technology Industrial Enterprise Intellectual Property Rights Application Pilot Enterprise" title.

In 2015, Changzhou Hongda's "steam efficient utilization technology based on intelligent control" was included in the National Key Energy-Saving and Low-Carbon Technology Promotion Catalog by the National Development and Reform Commission 。

In 2014, Changzhou Hongda's "digital control system for dyeing combined machine based on online detection" was listed as the first batch of water-saving technologies, processes, and equipment recommended by the Ministry of Industry and Information Technology 。

In 2005, Changzhou Hongda's "online detection of dyeing process parameters" won the Hong Kong Sangma Textile Technology First Prize 。

Changzhou Hongda takes "Innovation, Refinement, Excellence" as its product R&D philosophy, and carefully plans its company development. Currently, its technological dyeing has 6 major sections : online testing of dyeing process parameters, intelligent system for dyeing machines based on artificial intelligence technology, printing machine detection system, intelligent system for shaping machines based on the new generation of artificial intelligence technology, new generation fabric inspection system based on artificial intelligence technology, energy-saving and emission-reduction and automation control system.

To solve the industry's pain point of lacking whole flower and whole weft functions, Changzhou Hongda, after more than ten years of efforts, using existing image technology, invented the full-width scanning whole flower function, created image whole weft, and achieved mass production.

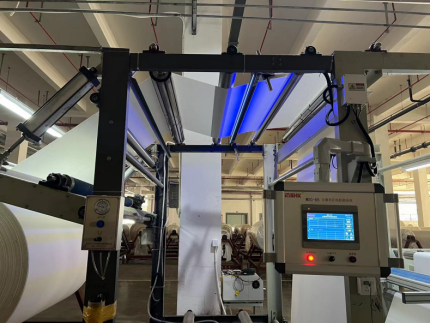

Hawk Vision ® Intelligent Image Whole Flower and Whole Weft Machine

Hawk Vision ® Intelligent Image Whole Flower and Whole Weft Machine It has internationally leading full-width scanning whole flower and whole weft technology. Using new technological means, it solves the problem of textile pattern deformation and the types that cannot be corrected by photoelectric whole weft machines, surpassing the value of photoelectric whole weft and ordinary image whole weft. Full-width scanning can have more than 8000 detection points, directly identifying the full-width pattern, achieving precise correction, and having advanced digital processing technology and big data analysis, breaking the various limitations of past traditional photoelectric whole weft machines and ordinary image whole weft machines.

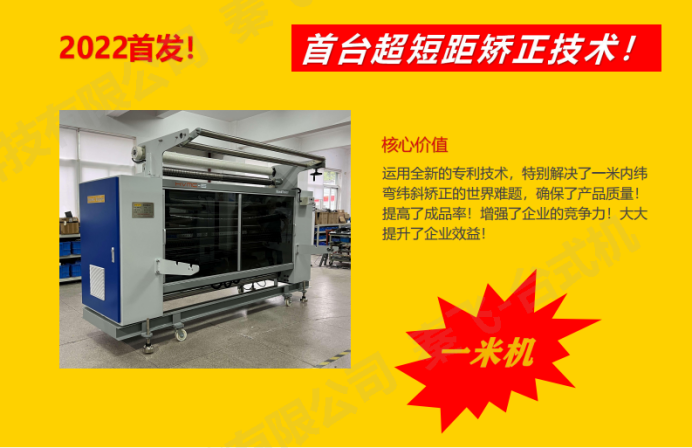

HVMC-22T AI Series of intelligent image weft straightening machines

First launched in 2022 HVMC-22T AI Series Intelligent Image Weft Straightening Machine Using new patented technology, it particularly solves the world's problem of correcting weft bending and weft skewing within one meter, ensuring product quality and yield.

HVMC-22HE Intelligent image weft straightening machine

HVMC-22HE Intelligent Image Weft Straightening Machine It is a new generation of weft straightening machine newly developed by Changzhou Hongda. It adopts full-width scanning detection technology for warp deformation and artificial intelligence deep learning technology to automatically identify the size of the fabric width, comprehensively detect the weft deformation in the entire width direction, accurately control the actuator, and realize the correction of weft deformation.

In addition to the industry-leading weft straightening and weft patterning system, Changzhou Hongda has also conducted in-depth development in the shaping machine intelligent system, including the world's original weight system. Changzhou Hongda's weight detection system can solve problems throughout the production process, solving the problem of weight measurement through digital technology

INSHK ® HV-GM200 Intelligent online fabric weight detector

INSHK ® HV-GM200 Intelligent Online Fabric Weight Detector As a global first, with multiple independent intellectual property rights, it can achieve real-time, direct, and accurate measurement of the actual production weight; it is connected to the density detection overfeeding system to directly build a closed-loop target weight control; it solves the fabric weight problems that exist through manual weighing; real-time fabric width detection; ensures product stability and improves product quality; real-time continuous online recording and storage of fabric weight, realizing historical data query; greatly reducing fabric loss during production.

Hawk Vision ® Density detection automatic overfeeding control system

Hawk Vision ® Density detection automatic overfeeding control system It adopts two sets of online weft density detection sensors for fabric infeed and outfeed to form a closed-loop detection and control system; it adopts a special light source design to meet the accurate measurement of weft density of fabrics with various colors and organizational structures, with a wide range of applications; the system can detect the weft density value of fabrics online in real time, output adjustment control signals to control the overfeeding amount of the overfeeding motor; ensure the uniformity and consistency of fabric weft density during production, effectively solve the problem of weft density difference between the head and tail, and improve product quality; it has a user-friendly human-machine interface, which can display the detection results in real time and is easy to operate; it has a database management function, which is convenient for users to control and manage production quality.

HV-T500 Intelligent shaping process system

HV-T500 Intelligent Shaping Process System It can truly present the shaping temperature and time of the fabric inside the drying room, and at the same time, it can effectively control the shaping temperature and shaping time of the shaped fabric, and match it with the process requirements. Through the shaping process management system, the actual presentation, recording, and storage of the shaping temperature and shaping time of the fabric inside the drying room and the temperature of the cloth clip are realized, and the environmental temperature and fabric surface temperature of each monitoring point are recorded. According to the reading speed, the actual shaping time of the fabric at the shaping temperature is analyzed to guide the production operation process, optimize the shaping process, and improve the one-time success rate of fabric shaping.

MSC-E Shaping machine intelligent exhaust energy-saving system

MSC-E Shaping Machine Intelligent Exhaust Energy-Saving System By adjusting the air vents and fan frequency in the oven, it achieves precise control of the air humidity, flue gas concentration, and pressure in the drying room of the existing shaping machine equipment, meets the requirements of process production, achieves energy saving and consumption reduction, and improves product quality.

HV-L100 Shaping machine filter status detection system

HV-L100 Shaping Machine Filter Status Detection System It solves the efficiency of heat conduction, greatly reducing energy consumption; it solves the problem of temperature difference between the edges and the center caused by clogging, avoiding uneven upper and lower hot air due to dust accumulation, which affects the shaping effect; real-time curve recording and display, which is convenient for viewing the real-time status of the filter; the system has a remote communication interface, providing data communication types and addresses as needed.

Intelligent fabric inspection system based on the new generation of artificial intelligence technology

Intelligent fabric inspection system based on the new generation of artificial intelligence technology Using visual processing technology and artificial intelligence technology to replace the currently common manual inspection, according to the organization and structural characteristics of textiles, training and deploying artificial intelligence models from the texture and gray levels of the image, combined with the requirements of the enterprise's process quality monitoring, real-time online detection of fabric quality.

Online fabric seam visual detection system

Online fabric seam visual detection system Using modern machine vision technology and artificial intelligence technology to replace the currently common manual inspection, it can display and record the seam spacing in real time, and can store or upload it according to customer requirements.

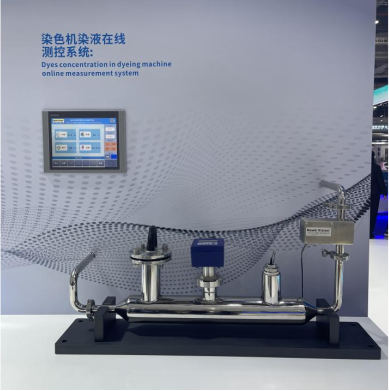

Dyeing machine dye online measurement and control system

Dyeing machine dye online measurement and control system It has an artificial intelligence analysis system that can collect production process data in real time and perform intelligent analysis and processing. According to the type of fabric, it intelligently optimizes the control mode to ensure the one-time success rate of dyeing and greatly improves the reproducibility of the production process; it realizes the transformation from traditional manual experience to the execution of the new generation of artificial intelligence; it realizes the monitoring of the entire dyeing production process; it reduces problems such as dyeing tank volume and batch difference, greatly improving the one-time success rate of dyeing; it saves dyes and auxiliaries, reduces labor production costs, and improves production efficiency.

MSC-U5 Online moisture content detection system

MSC-U5 Online Moisture Content Detection System Using the new INSHK full-width humidity sensor detection method, it solves the problems existing in the fabric drying process from both process and energy-saving aspects, improves the fabric processing quality and improves the feel and luster, adjusts the steam flow, and is of great significance to improving product quality and energy saving and emission reduction.

Creating core value for users with technology

Changzhou Hongda Technology has built its main core competitiveness from aspects such as technological innovation capabilities, product quality and stability, professional services, industry experience, and reputation. Changzhou Hongda Technology will continue to uphold the concept of "innovation, excellence, and excellence", continuously improve the company's core competitiveness, adhere to original innovation, technological self-reliance, solve the industry's "bottleneck" technological problems, create core value for users with technology, and promote the intelligent, green, and sustainable development of the textile industry.

03 Market-centric

Changzhou Hongda has occupied the commanding heights of the domestic and international markets and technology, leading technological advancements in the field. For over 30 years, Changzhou Hongda has been committed to technological innovation, utilizing digital twin technology to build a virtual, three-dimensional, and omnidirectional intelligent imaging online detection system for the real-world production processes of the textile printing and dyeing industry. This system continuously upgrades, integrates, monitors, and influences various aspects of the automated and digital production processes in the textile printing and dyeing industry. In addition, the company, based at the Hongda Intelligent Equipment Industry Development Research Institute, leverages national policies and scientific and technological innovation platforms to promote a series of products, R&D experience, and production concepts to more industrial fields, providing technological support and services for China's national strategy of technological innovation development. Changzhou Hongda, with its deep industry expertise and keen market insight, has seized market opportunities in the context of artificial intelligence's increasing market share, perfectly integrating artificial intelligence with printing and dyeing equipment to achieve "digitalization of processes, intelligence of equipment, and informatization of management." This improves production efficiency and product quality, enhances product precision, and promotes high-quality development of the industry.

Related News

Tel:+86-519-88856666

Fax:+86-519-85158666

Email:czhongda@czhongda.com.cn

Company Address: No. 220, Taishan Road, High-tech Zone, Changzhou, Jiangsu Province, China

Tiktok

Official Account

Copyright © Changzhou Hongda Intelligence Technology Co., Ltd.