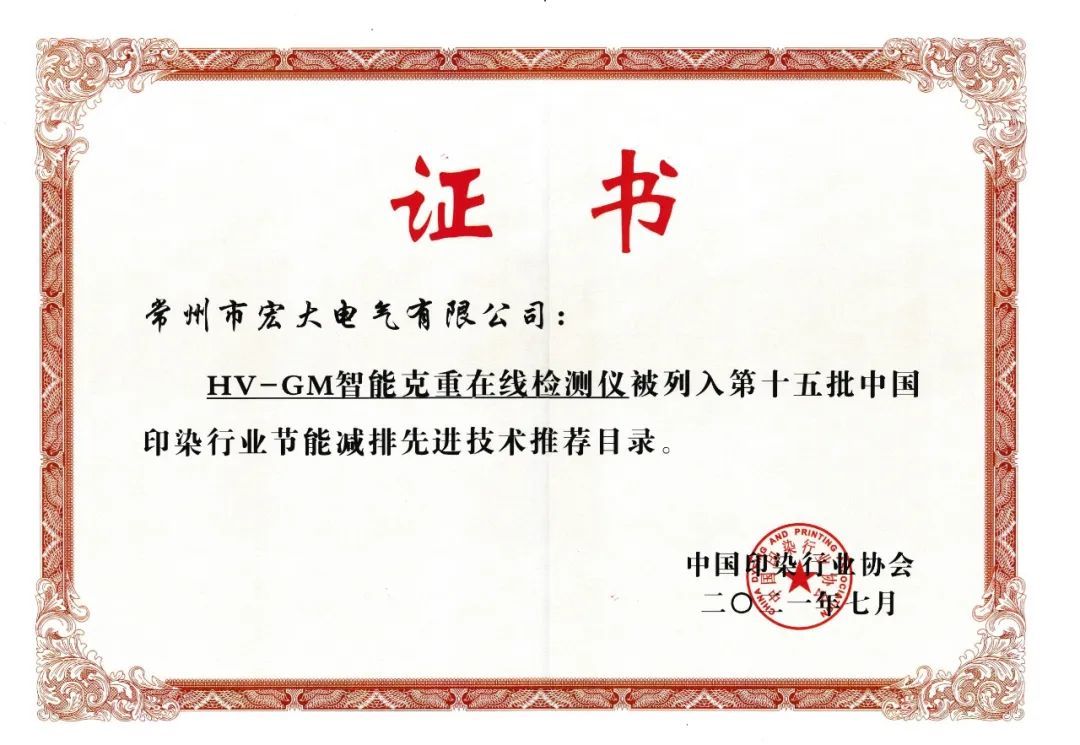

【Special Focus】Changzhou Hongda's pioneering product achieves a major breakthrough in grammage detection! The HV-GM intelligent online grammage detection instrument is included in the fifteenth batch of recommended advanced technologies for energy conservation and emission reduction in China's dyeing industry.

The printing and dyeing industry, as an important part of the textile industry, is increasingly prominent in the textile industry chain and is crucial for the green development of the textile industry.

The printing and dyeing industry, as an important part of the textile industry, is increasingly prominent in the textile industry chain and is crucial for the green development of the textile industry.

To accelerate the promotion and application of green and low-carbon technologies, promote the comprehensive green transformation of the printing and dyeing industry, and achieve high-quality development and high-level protection, the "Tongzhou Bay 2022 National Printing and Dyeing Industry Energy Conservation and Environmental Protection Annual Conference," hosted by the China Printing and Dyeing Industry Association and co-organized by the Tongzhou Bay Jiang-Hai Linkage Development Demonstration Zone Management Committee, was held in Nantong City, Jiangsu Province on August 11.

The conference discussed and exchanged views on the latest national environmental management policies, carbon emission reduction paths and technologies in the printing and dyeing industry, research and application of green and low-carbon technologies and equipment, and efficient treatment technologies for wastewater and waste gas from printing and dyeing. More than 100 experts, scholars, and enterprise representatives from the industry attended the event. The "15th Catalog of Recommended Advanced Technologies for Energy Conservation and Emission Reduction in China's Printing and Dyeing Industry" was released at the meeting.

Changzhou Hongda was among the list!

The HV-GM intelligent online weight detection instrument was included in the 15th Catalog of Recommended Advanced Technologies for Energy Conservation and Emission Reduction in China's Printing and Dyeing Industry.

At the meeting, Gu Ren, Chairman and General Manager of Changzhou Hongda Technology (Group), shared his insights on the topic of "Intelligent System for High-Efficiency Energy-Saving Digital Shaping Process."

With nearly 30 years of development history, Changzhou Hongda Technology Group has always adhered to the goal of achieving digital control of the printing and dyeing production process. Leveraging nearly 30 years of profound understanding and experience in the printing and dyeing industry, and through accumulated advanced detection and control technologies, it continuously researches and develops online detection products and intelligent equipment with world-leading technology levels for the printing and dyeing industry, continuously supporting the intelligent progress and high-quality development of textile printing and dyeing enterprises!

Gu, guided by the "14th Five-Year Plan for Comprehensive Energy Conservation and Emission Reduction," believes that the green development of the industry, a significant improvement in clean production levels, and an increase in resource and energy utilization efficiency remain crucial for the industry. Changzhou Hongda's successfully developed "INSHK finishing machine intelligent system" is a comprehensive upgrade of existing finishing machines. It is a complete finishing machine process execution system built through real-time online detection of multiple process parameters of textiles, big data, process internet, and artificial intelligence technology. It ensures the quality of textile finishing, builds a new generation of finishing machine control methods, and will significantly improve the level of intelligence of existing finishing processing.

In addition, he also introduced other latest technologies of Changzhou Hongda in printing and dyeing. Such as HawkVision intelligent image warping machine, HawkVision intelligent image flower warping machine based on artificial intelligence technology, HV-GM200 intelligent online weight instrument, Hawk Vision density detection automatic overfeeding control system, etc., interpreting the core role of intelligent manufacturing in printing and dyeing: accurate fabric feeding, timely and fast delivery; reducing labor and labor intensity, reducing dependence on the technical skills of operators; energy saving and emission reduction from the source, achieving green manufacturing; supporting the truly sustainable development of industrial manufacturing enterprises.

It is understood that the heat setting process is an important link in the post-finishing process of textile dyeing and finishing. Fabric weight and width are important indicators to measure whether the product is qualified during the heat setting process. For a long time, weight and width have been measured and controlled offline based on manual experience. The real-time status of fabric weight and width during continuous production cannot be understood. At the same time, offline weighing with a scale damages the textile, resulting in a low qualification rate of weight indicators, unstable product quality, and waste of finished products.

To address this problem, Changzhou Hongda, utilizing its strong technical advantages and R&D capabilities in online detection and control systems for printing and dyeing, has successfully developed the HV-GM intelligent online weight detection instrument through long-term research on finishing processes, technologies, and equipment. After the product was launched, it had a huge impact within the industry. The system represents the highest level in China and has multiple independent intellectual property rights. This time, the product was selected for the "15th Catalog of Recommended Advanced Technologies for Energy Conservation and Emission Reduction in China's Printing and Dyeing Industry."

The HV-GM intelligent online weight detection instrument can perform online detection and control of fabric weight during continuous production operations without the need for scale weighing. At the same time, it automatically measures and displays the fabric width, which is very helpful in improving the finishing process effect and product quality, and achieving process repeatability. It achieves energy saving and emission reduction from the source of production, reduces the risk of order processing, reduces the consumption of finished products, and thus significantly improves the profit margin of enterprises.

Related News

Tel:+86-519-88856666

Fax:+86-519-85158666

Email:czhongda@czhongda.com.cn

Company Address: No. 220, Taishan Road, High-tech Zone, Changzhou, Jiangsu Province, China

Tiktok

Official Account

Copyright © Changzhou Hongda Intelligence Technology Co., Ltd.