czhongda@czhongda.com.cn

czhongda@czhongda.com.cn

SEARCH...

SEARCH...

czhongda@czhongda.com.cn

czhongda@czhongda.com.cn

SEARCH...

SEARCH...

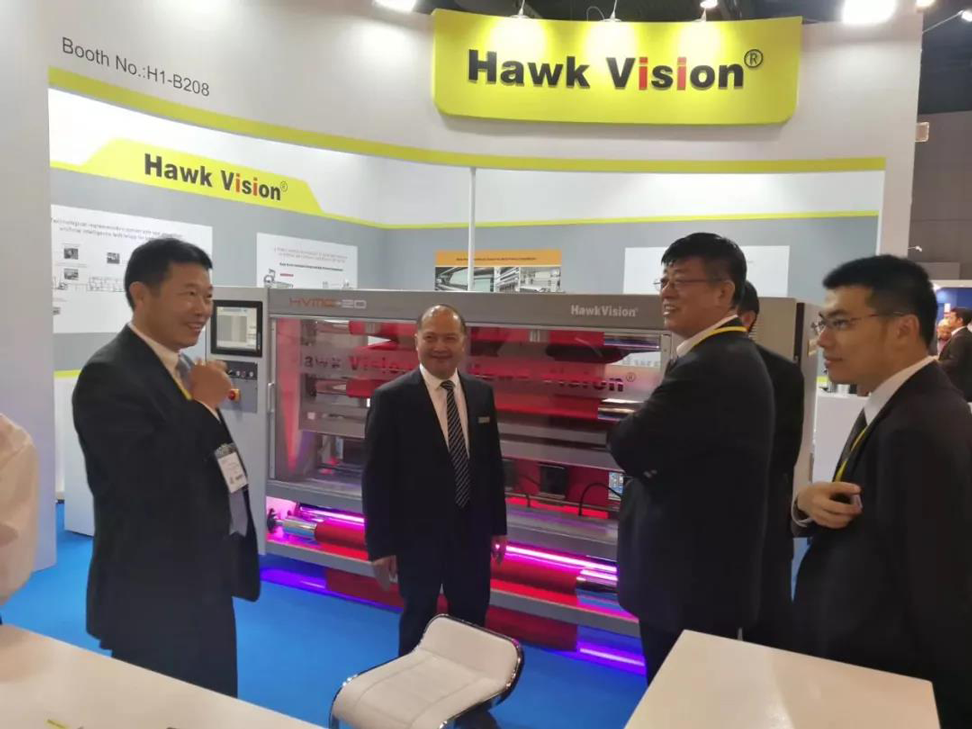

At this exhibition, Changzhou Hongda exhibited its HawkVision® intelligent image whole flower weft knitting machine at H1B208. The machine is based on its strong European technical background and Changzhou's profound technical research and development strength. It is the first internationally-advanced “full-width scanning whole-wedding technology”.

At the exhibition, Changzhou Hongda focused on the intelligent control system after textile printing and dyeing. According to Gu Ren, chairman of Changzhou Hongda, the HawkVision® intelligent image whole flower weft knitting machine introduced at the exhibition site applied a number of artificial intelligence technologies and realized some software. New features expand the adaptability of the variety. At present, these products have been produced and applied in many well-known textile printing and dyeing factories at home and abroad, and have exported 6 sets to Vietnam, which has greatly improved the level of intelligence for the enterprise, while saving labor, providing support for the success rate of products, and being favored by the market. Customer praise.

The Hawk Vision® intelligent image whole flower weft machine uses a new technology to completely solve the textile flower deformation, weft and weft bending problems that can not be corrected and recognized by photoelectric weft. It is suitable for dyed fabrics, printed fabrics and jacquard fabrics. , transfer printing, sanding cloth, knitted fabric, denim, sofa cloth, curtain fabric, twill fabric, heavy fabric, high-density high-density cloth, silk silk chiffon, digital printing sizing, composite processing, and other weaving textiles, breaking Photoelectric weft-aligning machine and ordinary image weft-aligning machine have various limitations on textile fabric weaving, texture, thickness, etc., surpassing the value of photoelectric weft and ordinary image weft.

The automatic on-line measurement and control system for knitted fabrics based on artificial intelligence technology used in this machine is listed in the “Recommended Catalogue of Advanced Technology for Energy Saving and Emission Reduction in China's Printing and Dyeing Industry” by China Printing and Dyeing Industry Association. The exhibiting products are self-developed and manufactured by the company and have 48 patents.

Speaking of artificial intelligence technology, Gu Ren, chairman of Changzhou Hongda, said: "Artificial intelligence has two key points in my opinion. The acquisition of data and the use of data are based on these two points. The road ahead is still very good. Long, technology is constantly prohibited, we will continue to accumulate sediment, lead the development of printing and dyeing automation, and help companies create core values."

In recent years, Changzhou Hongda has always adhered to technology as the entry point, and continuously deepened the in-depth study and research on printing and dyeing automation technology around the market demand. Every technological advancement of the company is derived from customer feedback and communication, which is the result of accumulation. ”

Based on its own strong technical reserves, in recent years, Changzhou Hongda has continuously promoted the deep integration of automation and industry from single-machine online inspection, network control of equipment, digital control of production process, and digital factory construction in printing and dyeing industry. Innovations are constantly being demonstrated.

Reprinted from textile machinery